In complex fluid systems, even the slightest fluctuation in flow can cause serious disruption, from incorrect instrument readings to product quality issues in manufacturing. Many engineers are constantly searching for valves that offer both precision and stability. Among the many types of valves available, the needle valve is specifically designed for accurate flow control. In this article, we’ll explore the concept, working principles, applications, and how to choose the right needle valve for your needs.

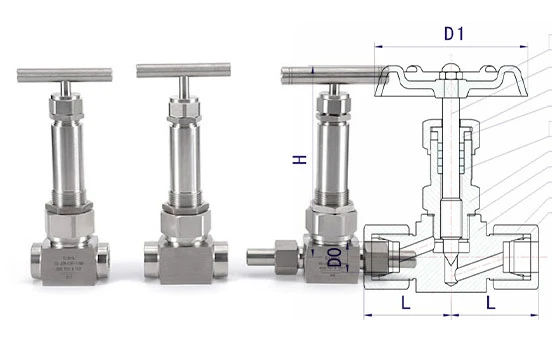

A needle valve is a valve that uses a finely threaded stem and needle-shaped plunger to gradually open or close the fluid path, allowing for precise flow regulation. It is commonly used in instrumentation systems, sampling lines, and low-flow, high-pressure applications where accuracy and leak-tight sealing are critical.

Though simple in appearance, its precision design makes it indispensable in industries like oil and gas, power generation, and chemical processing. Let’s take a closer look at how needle valves work and why they are so essential.

How Does a Needle Valve Work?

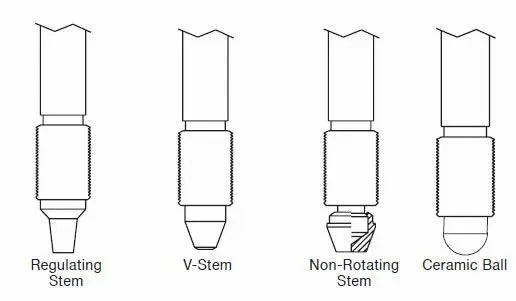

A needle valve operates by using a finely threaded valve stem to move a needle-like plunger up and down, allowing for fine-tuned control of fluid flow. When the operator turns the handle, the threads drive the needle gradually into or out of the valve seat, achieving progressive opening or closing.

Key Components:

- Valve Stem: Threaded shaft that moves the plunger

- Needle or Plunger: Tapered to provide gradual restriction

- Valve Seat: Precisely machined opening that seals the needle tip

- Handle: Usually round, allowing for fine manual adjustment

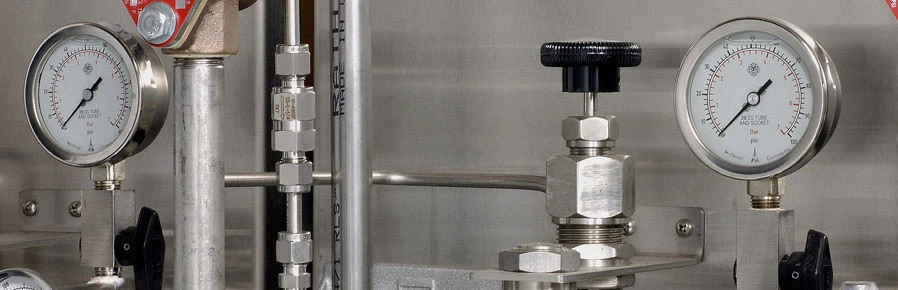

Unlike ball valves that provide quick open/close action, needle valves offer gradual, smooth regulation, making them ideal for calibration systems, gas flow control, and sample lines.

What Is the Function of a Needle Valve?

The primary function of a needle valve is to regulate, throttle, or shut off flow in systems that require fine control. It ensures:

- Controlled delivery of fluids to measuring instruments

- Accurate sampling in chemical and analytical labs

- Precise calibration of process equipment

- System safety through pressure relief and isolation

At Walter Valve, our needle valves feature tight sealing and pressure resistance up to 10,000 psi, making them suitable for both gas and liquid applications.

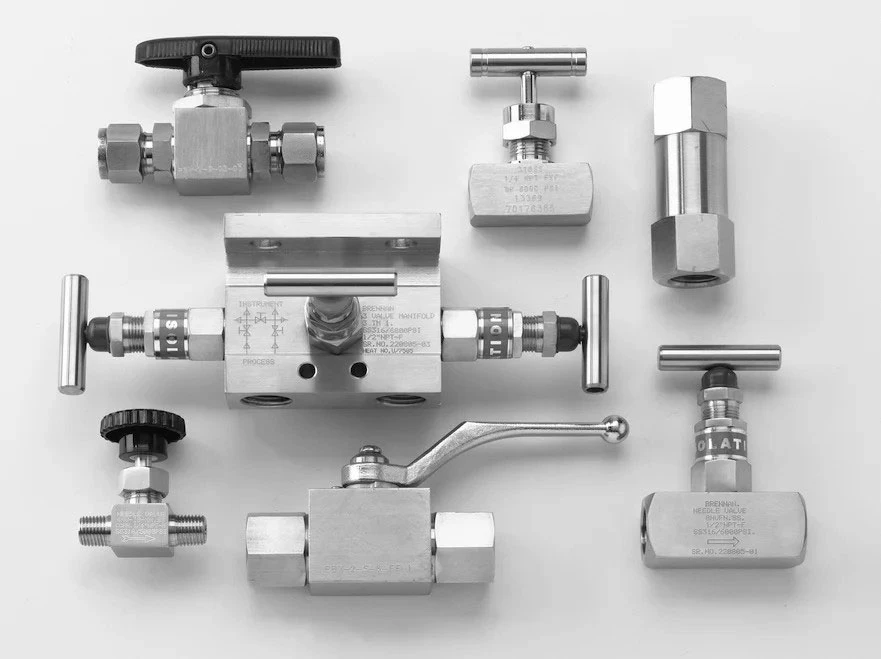

How Do Needle Valves Compare to Other Valves?

Many buyers confuse needle valves with other types such as ball valves, globe valves, or check valves. Here’s a comparison:

| Valve Type | Flow Control Precision | Typical Applications | Operation Speed |

|---|---|---|---|

| Needle Valve | Very High | Low-flow, precision systems | Slow |

| Ball Valve | Low | Shutoff, quick on/off | Fast |

| Globe Valve | Medium | General throttling | Moderate |

| Check Valve | N/A (non-return only) | Backflow prevention | Passive |

What sets the needle valve apart is its ability to provide both precision control and positive shutoff, especially under high pressure.

Where Are Needle Valves Used?

Needle valves are widely used across industries requiring precise flow control and high reliability:

- Oil & Gas

Used in wellhead control panels, sampling systems, and chemical injection units. Corrosion-resistant high-pressure needle valves are essential in upstream and midstream sectors. - Chemical and Petrochemical

Control precise dosing in reactors, regulate flow in analytical systems, and protect instruments from backflow or contamination. - Power Generation

Turbine steam and water lines require needle valves to manage small pressure valves and drain lines accurately. - Laboratories and Pharmaceuticals

High-purity needle valves regulate inert gases and liquids in lab equipment and pharmaceutical systems. - Water Treatment

Used in chlorine injection systems and control instruments for water quality monitoring.

Walter Valve offers needle valves in stainless steel, brass, and alloy grades to meet various chemical compatibility requirements.

What Sizes and Materials Are Available?

Needle valves come in a variety of sizes, pressure ratings, and materials depending on the application:

| Feature | Options |

|---|---|

| Size Range | 1/8″ to 2″ (Threaded NPT, BSP, and compression) |

| Pressure Rating | Up to 10,000 psi (690 bar) |

| Materials | SS316, SS304, Brass, Monel, Hastelloy |

| End Connections | Male/female threads, compression, flanged |

| Packing Options | PTFE, graphite, O-ring based |

Walter Valve provides custom machining and OEM branding for bulk orders to meet specific customer needs.

How to Choose the Right Needle Valve?

When selecting a needle valve, consider the following parameters:

- Media Type: Is the fluid corrosive, toxic, or high temperature?

- Pressure & Temperature: Choose materials and seals accordingly.

- Flow Rate: Smaller orifice = finer control; larger orifice = higher flow.

- Connection Type: Ensure compatibility with your system threads or flanges.

- Compliance Requirements: Standards such as API, ASME, NACE, or PED may apply.

Tip: For corrosive or offshore environments, SS316 or Monel needle valves with graphite packing are ideal for long-term reliability.

Benefits of Using Walter Valve Needle Valves

- Precision Machining: Fine tapered needles ensure smooth control

- Leak-Tight Sealing: Metal-to-metal or soft seat options

- Ample Inventory: Fast delivery for bulk or urgent orders

- Customization: Logo engraving, special threads, and coatings

- Factory Pricing: Direct from our 3,000 m² valve manufacturing facility

FAQ

Are needle valves suitable for high-pressure systems?

Yes. Needle valves are designed for high-pressure environments. Walter Valve offers models rated up to 10,000 psi.

Can needle valves control gas flow?

Absolutely. They are ideal for regulating compressed air, nitrogen, oxygen, and inert gases in instrumentation systems.

Can I use a needle valve for shutoff?

Yes. While mainly used for control, needle valves also provide effective shutoff, especially with clean or low-viscosity media.

What’s the difference between straight and angle needle valves?

Straight valves have inline connections. Angle valves redirect flow 90°, ideal for space-saving installations.

Conclusion

Needle valves play a critical role in ensuring flow precision, system safety, and process efficiency across industries. Whether you’re designing a control panel for offshore drilling or specifying components for a pharmaceutical lab, choosing the right needle valve can significantly impact system performance.

Walter Valve manufactures and supplies a full range of needle valves with factory-direct pricing, fast delivery, and performance assurance. Our engineers are ready to help you choose or customize the valve that best suits your needs.

Contact us at info@waltervalves.com for quotes or technical project support.