Selecting the right check valve material may seem like a minor technical detail, but the consequences of choosing the wrong one can be costly. Many industrial buyers struggle with premature valve failure, chemical corrosion, or system inefficiencies, often because the valve material didn’t match the application. This makes understanding the key differences between metal and plastic check valves more urgent than ever. In this guide, we compare performance, longevity, cost, and typical use cases to help you choose the best option for your specific industrial needs.

Metal check valves offer higher durability, pressure tolerance, and temperature resistance, making them ideal for demanding industrial environments. Plastic check valves are lighter, more corrosion-resistant, and cost-effective, suitable for chemical, water treatment, and low-pressure systems. The choice depends on application-specific factors like pressure, temperature, media type, and budget.

Why This Question Matters

Choosing the right valve type affects not just the performance of your system, but also safety, maintenance cycles, and long-term cost. At Walter Valves, we’ve worked with global buyers who have faced issues ranging from leakage to complete system failure simply because the material wasn’t optimized for the task.

For example, one buyer from a Southeast Asian petrochemical facility used plastic check valves to save on costs, only to experience seal deformation and media leakage within 2 months due to high temperatures and backpressure. Once upgraded to stainless steel check valves, the same line has run maintenance-free for over 3 years. These are not rare cases—they’re common across many industries.

What Are the Main Differences Between Metal and Plastic Check Valves?

The fundamental differences lie in performance under pressure, chemical compatibility, weight, longevity, and overall cost of ownership. Let’s break it down:

| Feature | Metal Check Valves | Plastic Check Valves |

| Materials | Stainless steel, brass, bronze | PVC, CPVC, polypropylene |

| Pressure Rating | High (up to 10,000 psi for some alloys) | Low to medium (typically < 500 psi) |

| Temperature Range | Wide (-50°C to >300°C) | Limited (-20°C to ~90°C) |

| Corrosion Resistance | Good to excellent (with correct alloys) | Excellent in corrosive environments |

| Durability | Excellent (mechanical/thermal) | Good (in stable, chemical environments) |

| Weight | Heavier | Lightweight |

| Cost | Higher upfront cost | Lower upfront cost |

| Serviceability | Repairable, longer life | Often non-repairable, replaceable |

| Applications | Steam, oil, gas, high-pressure systems | Water lines, chemical dosing, irrigation |

Which Lasts Longer in Industrial Use?

Metal check valves typically last longer, especially in harsh or dynamic environments. Stainless steel models, for instance, can operate continuously for 10 years or more in high-pressure systems. Their robustness makes them ideal for oil & gas, marine, steam, and power generation.

Plastic check valves, while excellent in static and non-abrasive chemical environments, may degrade over time when exposed to UV, pressure spikes, or extreme temperatures. That said, in non-demanding settings like irrigation or low-pressure chemical dosing, they can last up to 5-7 years reliably.

Key takeaway: Metal valves have better fatigue resistance, while plastic valves offer good longevity in chemically aggressive but mechanically gentle conditions.

When Should You Use a Plastic Check Valve?

Plastic check valves should be your go-to in these conditions:

- Highly corrosive fluids: Acids, alkalis, brine, chlorinated water

- Low pressure systems: Under 300 psi

- Cost-sensitive projects: Where low replacement cost is important

- Non-critical lines: Where occasional replacement is acceptable

- Non-metallic piping systems: Where weight and chemical compatibility matter

Industries where plastic check valves excel:

- Water & wastewater treatment

- Aquaculture

- Chemical dosing in labs and pools

- Food & beverage (non-hot media)

- Residential or commercial irrigation

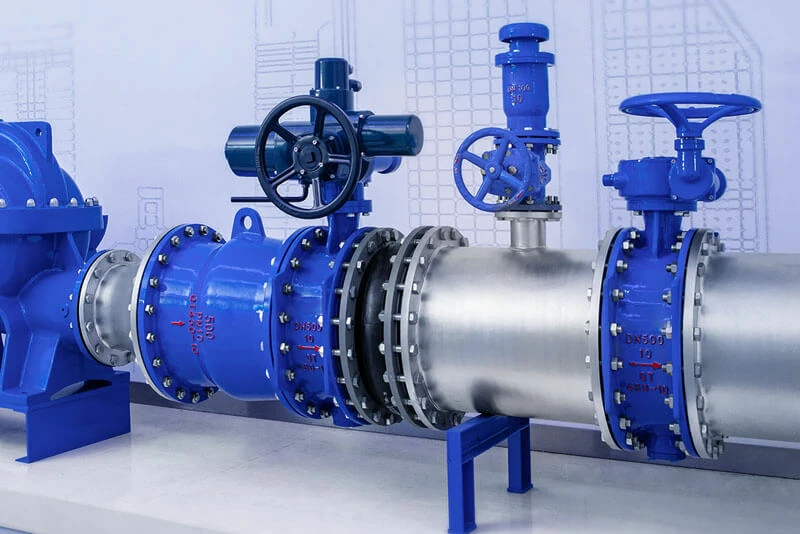

Why Are Metal Check Valves Standard in Heavy Industry?

In critical environments, failure is not an option. Metal check valves are preferred for their:

- High pressure endurance: Especially in hydraulic, gas, and steam systems

- Thermal stability: Function well under thermal cycling and temperature spikes

- Abrasion resistance: Ideal for slurries or mixed-phase flows

- Repairability: Can be re-sealed or cleaned

At Walter Valves, our metal check valves are used globally in:

- Instrumentation and process control skids

- Oilfield and gas pipelines

- Marine engine systems

- Power plant steam turbines

Engineers and plant managers prefer metal when failure would mean downtime, safety risk, or high repair costs.

How Do They Compare in Cost?

The cost of check valves is about more than price tags. Here’s a comparative breakdown:

| Valve Type | Unit Cost | Lifespan | Total Cost of Ownership (TCO) |

| Plastic (PVC/PP) | $5–$30 | 2–6 years | Low for mild conditions |

| Metal (SS/Brass) | $25–$150+ | 8–15 years | Low for high-demand applications |

If you’re in a high-turnover environment where maintenance is frequent, the long lifespan and repairability of metal check valves justify the upfront investment.

Are Plastic Valves Chemically Resistant?

Absolutely. PVC, CPVC, and polypropylene are all highly resistant to many corrosive media. Some examples:

PVC: Handles sodium hypochlorite, sulfuric acid, seawater

CPVC: Higher heat tolerance, excellent in hot acid systems

PP: Great for solvents, bleach, and oxidizing agents

Just be aware of their limitations with:

Aromatic hydrocarbons (e.g. benzene)

UV exposure (use UV-stabilized grades)

Extreme pressure/temperature combinations

What About Maintenance?

Metal check valves are built for longevity and serviceability. With replaceable seats, o-rings, and springs, they can often be cleaned and reused multiple times.

Plastic valves, especially smaller molded ones, are usually considered disposable. Once internal parts wear or degrade, the whole valve is replaced.

If your maintenance team needs valves they can service without full replacement, metal is clearly the better choice.

Weight and Installation Considerations

Weight can be a serious concern in:

Wall-mounted piping systems

Offshore skids

Compact or elevated assemblies

Plastic valves are easier to handle and install, especially in tight or elevated areas. For example, a 2″ metal valve might weigh 6–8 kg, while its plastic equivalent weighs under 1.5 kg.

If weight and ease of installation are important, plastic wins.

Which Valve Is Right for Your Industry?

| Industry | Best Material | Reason |

| Oil & Gas | Metal | High pressure, rugged environment |

| Chemical Manufacturing | Plastic or Metal | Depends on media and pressure |

| Water & Wastewater Treatment | Plastic | Low pressure, corrosion-prone media |

| Power Generation | Metal | Steam and temperature stress |

| Food & Beverage | Plastic (NSF) | Non-toxic, chemical-free environments |

| Mining & Slurry Systems | Metal | Abrasion and pressure resistance |

| Residential/Commercial HVAC | Plastic or Metal | Depends on flow media and cost |

Conclusion:

There’s no universal answer. The choice between metal and plastic check valves should be application-driven:

Choose metal if your system involves high pressure, temperature, or mechanical stress.

Choose plastic if you need low-cost, corrosion-resistant valves for chemically aggressive but low-demand conditions.

At Walter Valves, we manufacture and stock a full range of both metal and plastic check valves. With over 3,000 m² of production space, advanced CNC machines, and a professional QA team, we guarantee quality, performance, and quick delivery.

Ready to Choose?

Email us: info@waltervalves.com

Visit our Alibaba store or official website

Request a quote for your project specs

Got questions? Drop them in the comments or reach out directly.

Found this guide useful? Share it with your engineering team or procurement network.

Stay connected for more technical guides from Walter Valves!