In high-pressure industrial systems, sudden pressure spikes can lead to catastrophic equipment failure, safety hazards, and costly downtime. Many engineers and purchasing managers struggle to select the right protection mechanisms for these systems. Without the proper valve installed, even a small malfunction could escalate into a serious incident. That’s where relief valves come into play—automatically safeguarding systems by releasing excess pressure before damage occurs.

صمامات الإغاثة are safety devices designed to automatically open at a preset pressure to release excess fluid or gas, thereby preventing overpressure in a system. Once the pressure returns to safe levels, the valve closes again to resume normal operation.

Why Are Relief Valves Necessary?

Pressure relief is a fundamental safety requirement in any pressurized system, including pipelines, gas distribution, chemical processing, and hydraulic equipment. Without a relief valve, pressure accumulation could exceed the design limits of the pipes or components, leading to:

- Burst pipes or vessels

- Fire or explosion in flammable environments

- Equipment damage and operational downtime

- Environmental or hazardous material leaks

- Personnel injury or fatalities

Installing properly rated صمامات التنفيس ensures compliance with safety standards and helps maintain system reliability.

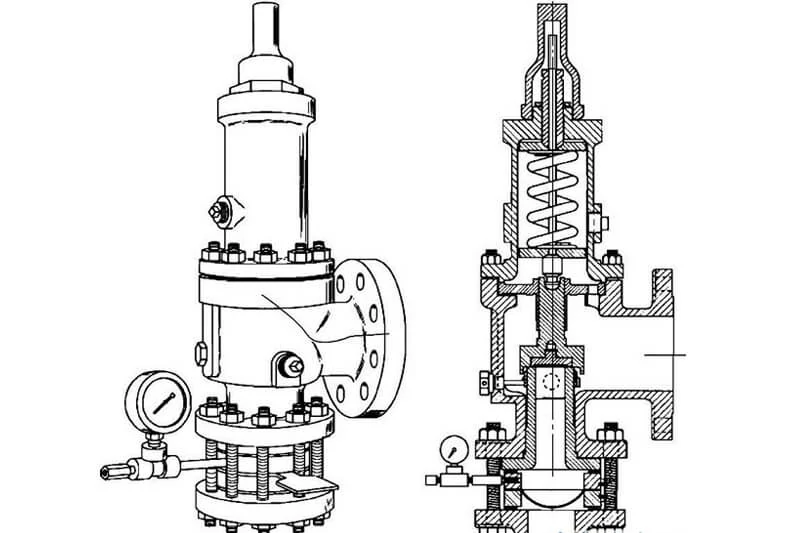

What Is the Basic Working Principle of a Relief Valve?

A relief valve functions on a force balance principle—when the internal system pressure exceeds a pre-calibrated threshold, it overcomes the spring force or pneumatic counterforce holding the valve closed.

Main components include:

- Inlet port: Connects to the pressurized system

- Valve seat and disc: The sealing surface

- Spring or actuator: Provides the opposing force

- Adjustment screw: Sets the pressure threshold

When the system pressure pushes beyond the spring force:

The disc lifts from the seat.

Excess fluid or gas is discharged through the outlet.

Once pressure drops below the set point, the spring re-seats the disc, stopping the flow.

What Types of Relief Valves Are Common in Industrial Applications?

There are several types of relief valves depending on media, application, and precision required:

1. Spring-Loaded Relief Valve

Most common

Mechanical spring tension defines opening pressure

Suitable for gases and liquids

2. Pilot-Operated Relief Valve

Uses a smaller pilot valve to control a larger main valve

More stable and accurate for high-pressure, large-flow applications

3. Balanced Relief Valve

Designed to counteract backpressure

Ideal for fluctuating system environments

4. Thermal Relief Valve

Specifically used to protect against thermal expansion in liquids (e.g., oil pipelines exposed to sun)

5. Safety Relief Valve (SRV)

Combines features of safety valve and relief valve

Opens gradually or instantly depending on the pressure increase rate

Where Are Relief Valves Typically Used?

Relief valves are found in various critical industries:

- Oil and gas pipelines: To prevent pressure build-up

- Chemical processing plants: For corrosive or hazardous fluids

- Boilers and steam systems: As a fail-safe against explosion

- Hydraulic equipment: To avoid seal failure and fluid leaks

- Air compressors: To vent overpressure automatically

- Cryogenic systems: For LNG/LPG applications

في صمامات والتر, our صمامات التنفيس are engineered for high-performance instrumentation and control applications in these very environments.

How to Select the Right Relief Valve?

Selecting a relief valve involves evaluating multiple parameters:

| Selection Criteria | Considerations |

| Set pressure | Match to maximum allowable working pressure (MAWP) |

| Flow capacity | Based on expected overpressure discharge rate |

| Media compatibility | Liquid, gas, steam, corrosive materials |

| Material of construction | Stainless steel, brass, special alloys |

| نوع الاتصال | Threaded, flanged, welded |

| Certifications | ASME, API, ISO based on region or industry |

Tip: Always consult your system’s design pressure and expected operating conditions before choosing a valve.

What Is the Difference Between a Relief Valve and a Safety Valve?

| الميزة | صمام الإغاثة | Safety Valve |

| Opening behavior | Gradual opening | Sudden full opening |

| التطبيق | Liquid systems | Gas/steam systems |

| Use case | Hydraulic, thermal expansion, fluid tanks | Boilers, pressure vessels |

| Design pressure range | Moderate to high | High pressure |

While both are pressure release devices, صمامات التنفيس are tailored for gradual pressure control, whereas safety valves respond instantly to dangerous surges.

How to Maintain a Relief Valve for Long-Term Use?

To ensure your system stays protected, regular maintenance is essential:

- الفحص: Check for corrosion, debris, or spring wear

- Leak test: Confirm seat tightness and closure integrity

- Calibration: Re-verify set pressure annually or per regulations

- Replacement: Swap out aging components or whole valves periodically

في صمامات والتر, we offer durable, low-maintenance relief valves that withstand tough industrial conditions.

What Are Common Signs of a Failing Relief Valve?

If any of these occur, it’s time to inspect or replace:

- Valve leaks when it should be sealed

- Failure to open at the set pressure

- Valve remains stuck open after pressure drops

- Noisy discharge or vibration during operation

Faulty valves not only compromise safety but can also trigger regulatory violations or system downtime.

الخاتمة

Relief valves play a crucial role in industrial system safety, ensuring overpressure protection for liquid and gas systems alike. By understanding how they work, the different types available, and how to select and maintain them, purchasing managers and engineers can prevent costly failures and ensure reliable system performance.

في صمامات والتر, we manufacture and supply a full range of صمامات التنفيس and other instrumentation products—designed with performance, durability, and global B2B buyers in mind.

اتصل بنا اليوم في info@waltervalves.com or visit our Alibaba store to request a quote or product catalog.