فحص الصمامات هي مكونات أساسية في أنظمة الأنابيب، وهي مصممة للسماح للسائل بالتدفق في اتجاه واحد مع منع التدفق العكسي الذي قد يتسبب في تلف أو عدم الكفاءة. إن فهم مكان وكيفية تركيب هذه الصمامات أمر بالغ الأهمية لسلامة النظام وأدائه وطول عمره. تستكشف هذه المقالة التطبيقات الرئيسية، والأنواع، وأفضل ممارسات التركيب للصمامات الفحصية - بما في ذلك الصمامات الفحصية المتأرجحة وغيرها من الأصناف الشائعة - عبر أنظمة المياه والأنظمة الصناعية والهيدروليكية. صمامات الفحص هي أجهزة ميكانيكية تستخدم في أنظمة الأنابيب لمنع التدفق العكسي وضمان التدفق أحادي الاتجاه. يتم تركيبها عادةً في خطوط تصريف المضخات وخطوط أنابيب المياه وأنظمة التدفئة والتهوية وتكييف الهواء والعمليات الصناعية لحماية المعدات والحفاظ على سلامة النظام.

استمر في القراءة لمعرفة المزيد عن وظيفة الصمامات اللاارتدادية وأنواعها وممارسات التركيب المثلى للصمامات اللاارتدادية في مختلف التطبيقات.

ما هي وظيفة صمام الفحص في نظام الأنابيب؟

تتمثل الوظيفة الأساسية للصمام اللا ارتدادي في منع التدفق العكسي في نظام الأنابيب. وهذا أمر بالغ الأهمية لتجنب المطرقة المائية، وحماية المضخات والضواغط من التلف، والحفاظ على الاتجاه المطلوب للتدفق في عمليات مثل الري والحقن الكيميائي وتوصيل الوقود. ومن خلال الإغلاق التلقائي عند انعكاس التدفق، تساعد الصمامات اللا ارتدادية في الحفاظ على الضغط وتقليل فقد الطاقة وتعزيز السلامة التشغيلية. إن تشغيلها البسيط والفعال في نفس الوقت يجعلها لا غنى عنها في بيئات الضغط المنخفض والعالي على حد سواء.

ما هي أنواع صمامات الفحص للاستخدامات المائية والصناعية؟

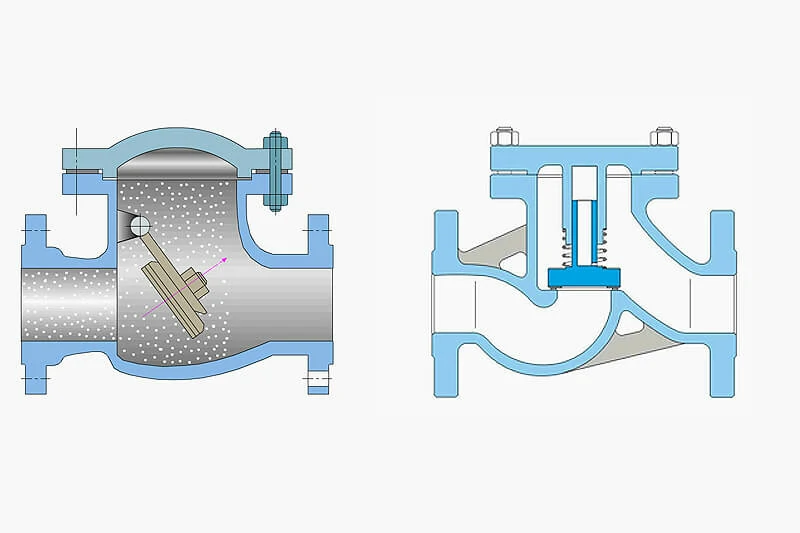

هناك عدة أنواع من صمامات الفحص، كل منها مناسب لتطبيقات محددة بناءً على التصميم وتصنيف الضغط وخصائص التدفق. تعد صمامات الفحص المتأرجحة من بين أكثر الصمامات شيوعًا، حيث تتميز بقرص مفصلي يتأرجح مفتوحًا مع التدفق الأمامي ويغلق عند توقف التدفق أو انعكاسه. وهي مثالية لأنظمة المياه ومياه الصرف الصحي نظرًا لانخفاض ضغطها المنخفض وقدرتها على التعامل مع الأحجام الكبيرة. تشمل الأنواع الأخرى صمامات فحص الرفع، وهي أفضل لتطبيقات الضغط العالي؛ وصمامات فحص كروية، وغالبًا ما تستخدم في أنظمة الضخ والقياس؛ وصمامات فحص مزدوجة اللوحة، وهي مدمجة ومناسبة لخدمات النفط والغاز والخدمات الصناعية. يقدم كل نوع مزايا فريدة من نوعها اعتمادًا على وسيط السائل ومعدل التدفق وبيئة التركيب.

أين يشيع استخدام صمام الفحص في أغلب الأحيان؟

تستخدم صمامات الفحص على نطاق واسع في العديد من القطاعات لضمان التحكم الآمن والفعال في السوائل. في أنظمة إمدادات المياه، يتم تركيبها بعد المضخات لمنع التدفق العكسي وتجنب تلف المضخة. كما أنها شائعة أيضًا في أنظمة التدفئة والتهوية وتكييف الهواء (HVAC) للحفاظ على اتجاه تدفق المبرد وسائل التبريد. تستخدم المنشآت الصناعية صمامات فحص في المعالجة الكيميائية وخطوط البخار وأنظمة توصيل الوقود لحماية المعدات الحساسة ومنع التلوث. بالإضافة إلى ذلك، توجد في أنظمة مكافحة الحرائق وخطوط أنابيب الصرف الصحي وشبكات الري، حيث يمكن أن يؤدي التدفق العكسي إلى فشل التشغيل أو المخاطر البيئية.

أين يتم تركيب صمام فحص على مضخة المياه؟

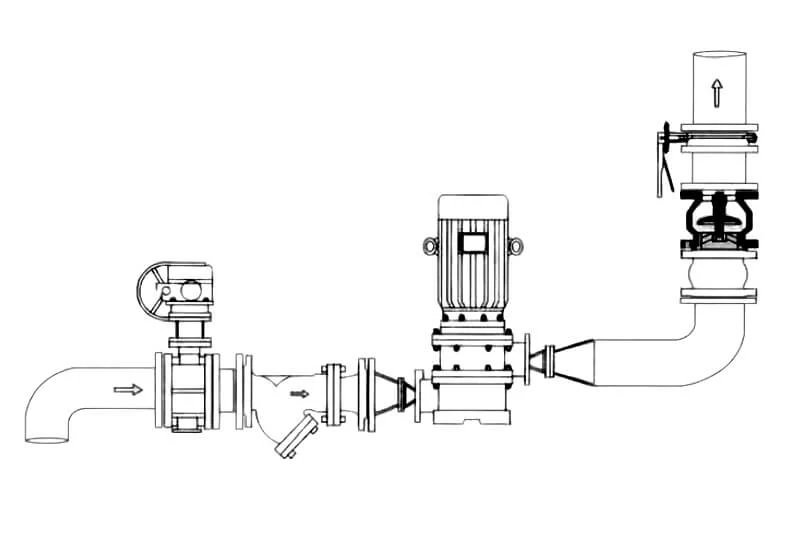

إن تركيب صمام لا ارتجاعي على مضخة المياه أمر بالغ الأهمية لمنع التدفق العكسي الذي يمكن أن يتسبب في تلف المضخة أو فقدان الطاقة. يجب وضع الصمام على جانب التفريغ من المضخة، ويفضل أن يكون قريبًا من مخرج المضخة. يضمن هذا الموقع أنه عندما تتوقف المضخة، يغلق الصمام اللا ارتدادي على الفور لمنع تدفق المياه إلى الخلف، مما قد يؤدي إلى دوران دافع المضخة في الاتجاه المعاكس ويسبب إجهادًا ميكانيكيًا. في تطبيقات المضخات الغاطسة، غالبًا ما يتم تركيب الصمام اللا ارتدادي فوق المضخة لحجز الماء في أنبوب العمود ومنع التصريف الخلفي. يتضمن التركيب السليم أيضًا النظر في الاتجاه - يجب تركيب معظم الصمامات اللا ارتدادية أفقيًا أو رأسيًا بناءً على تصميمها لتعمل بشكل صحيح.

هل يجب عليك استخدام صمام فحص لخزان المياه أو خط المياه؟

نعم، يوصى بشدة باستخدام صمامات فحص لكل من خزانات المياه وخطوط المياه. في أنظمة تخزين المياه، يمكن للصمام اللا ارتدادي المثبت في مدخل الخزان أن يمنع المياه المخزنة من التدفق مرة أخرى إلى خط الإمداد عند إيقاف تشغيل المضخة. هذا الأمر مهم بشكل خاص في الخزانات العلوية أو أنظمة المياه المعززة حيث يمكن أن يحدث السحب الخلفي. في خطوط توزيع المياه، تساعد صمامات الفحص في الحفاظ على الضغط ومنع التلوث بين مصادر المياه الصالحة للشرب وغير الصالحة للشرب. كما أنها تُستخدم في أنظمة إعادة تدوير الماء الساخن لضمان ثبات اتجاه التدفق والتحكم في درجة الحرارة.

ما هو دور صمام الفحص في الأنظمة الهيدروليكية؟

في الأنظمة الهيدروليكية، تلعب الصمامات اللاعكسية دورًا حيويًا في التحكم في اتجاه تدفق السوائل لضمان التشغيل السلس والآمن للآلات. يتم استخدامها لقفل السوائل في الأسطوانات، والحفاظ على الضغط في الدوائر، وحماية المضخات من التدفق العكسي. على سبيل المثال، في المكبس الهيدروليكي أو معدات الرفع، يمكن للصمام اللا ارتدادي أن يمنع الحمل من الانخفاض بشكل غير متوقع في حالة فقدان الضغط. غالبًا ما يتم استخدام الصمامات اللا ارتدادية التي تعمل بنظام التشغيل التجريبي في الأنظمة الهيدروليكية المتقدمة للسماح بالتدفق الحر في اتجاه واحد والتدفق المتحكم فيه في الاتجاه الآخر، مما يعزز الدقة والسلامة في تطبيقات مثل معدات البناء، وأتمتة التصنيع، وأنظمة الفضاء الجوي.

هل يمكنك وضع صمام فحص في أي مكان في الخط؟

في حين أن الصمامات اللاارتدادية متعددة الاستخدامات، إلا أنه لا يمكن تركيبها بشكل اعتباطي داخل نظام الأنابيب. ويعتمد وضعها على عوامل مثل اتجاه التدفق، وظروف الضغط، وإمكانية الوصول، ونوع الصمام المحدد. على سبيل المثال، تتطلب صمامات الفحص المتأرجحة مساحة كافية لفتح القرص بالكامل ويجب تركيبها عادةً في الأنابيب الأفقية. أما صمامات فحص الرفع والصمامات الكروية فهي أكثر مرونة ويمكن استخدامها غالبًا في التدفقات الرأسية. من الضروري اتباع إرشادات الشركة المصنعة والمعايير الهندسية لتجنب مشاكل مثل المطرقة المائية أو الاهتزاز أو التآكل المبكر. يمكن أن يؤدي التركيب غير الصحيح إلى فشل الصمام أو انخفاض الكفاءة أو حتى تلف النظام.

الخاتمة

لا غنى عن صمامات الفحص للحفاظ على اتجاه التدفق، وحماية المعدات، وضمان موثوقية النظام عبر مختلف التطبيقات - من إمدادات المياه والتدفئة والتهوية وتكييف الهواء إلى المعالجة الصناعية والمكونات الهيدروليكية. يعد اختيار النوع الصحيح من الصمامات وتركيبه بشكل صحيح أمرًا أساسيًا لتحقيق أقصى قدر من الأداء وطول العمر. إذا كنت تبحث عن صمامات فحص عالية الجودة، بما في ذلك صمامات الفحص المتأرجحة والتصميمات المتخصصة للاستخدام المائي أو الصناعي، ففكر في استشارة مورد موثوق به. للحصول على مشورة الخبراء والمنتجات الموثوق بها، لا تتردد في الاتصال بنا أو زيارة صفحة منتجاتنا لاستكشاف مجموعة الحلول المصممة خصيصًا لتلبية احتياجات نظام الأنابيب الخاص بك.