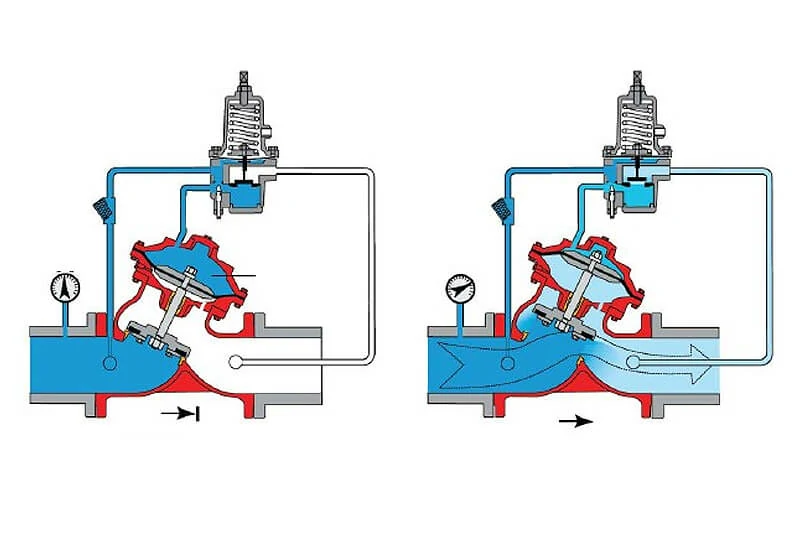

How Do Relief Valves Work?

In high-pressure industrial systems, sudden pressure spikes can lead to catastrophic equipment failure, safety hazards, and costly downtime. Many engineers and purchasing managers struggle to select the right protection mechanisms for these systems. Without the proper valve installed, even a small malfunction could escalate into a serious incident. That’s where relief valves come into play—automatically […]

How to Install Needle Valve: Step-by-Step Installation for Industrial Systems

Industrial fluid systems rely on precision and reliability—but even the best components fail if they’re not installed correctly. Many engineers struggle with installing needle valves, leading to leaks, pressure drops, or valve failure. These issues can halt operations and create safety hazards. Fortunately, proper installation of a needle valve is straightforward when you follow the […]

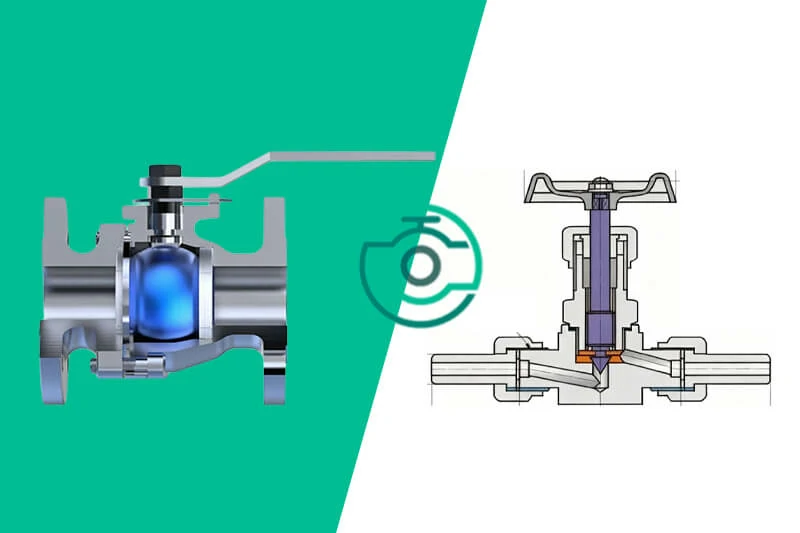

Ball Valve vs Needle Valve: Key Differences

Choosing the right valve can be confusing—especially when deciding between ball valves and needle valves. Selecting the wrong one may result in poor flow control, safety issues, or system inefficiency. This article will break down their structural and functional differences so you can make more informed, cost-effective purchasing decisions. Ball valves offer quick shutoff and […]

Where to Use a Double Block and Bleed Valve?

In critical fluid systems, leakage is not just a nuisance—it’s a serious safety and operational risk. Many industrial buyers struggle to select the right valve for high-integrity isolation. When standard valves fall short, double block and bleed valves offer a secure, space-saving solution for mission-critical applications. A double block and bleed valve (DBB) is used in […]

What Does a Metering Valve Do?

In fluid control systems, accuracy and consistency are everything. But many buyers and engineers struggle to distinguish between common valve types—especially when it comes to fine flow control. Selecting the wrong valve could mean imprecise dosing, unstable system performance, or costly overuse of fluids. That’s why understanding what a metering valve does—and where it fits […]

What Is a Bleeder Fitting?

In industrial systems, trapped pressure can be dangerous, maintenance delays costly, and improper venting a recipe for system failure. Many engineers and buyers underestimate the importance of small components like bleeder fittings—until something goes wrong. That’s why understanding what a bleeder fitting is, how it works, and where it applies is critical for ensuring safe […]

How to Install Press-In Grease Fittings

Many technicians and maintenance teams often ask how to properly install press-in grease fittings without leaks or premature failure. Incorrect installation can cause grease blow-out, loose fittings, or even bearing damage—especially in heavy-duty systems. This guide explains the correct installation method so you can ensure secure, reliable lubrication in all industrial applications. To install a […]

Metering Valve Comprehensive Guide

Industrial engineers and buyers often ask what a metering valve is and whether it differs from a needle valve or other flow-control components. Misunderstanding this leads to poor flow stability, inaccurate dosing, and unnecessary system downtime. To solve these issues, this guide explains what a metering valve does, how it works, and how to choose […]

What Is a Bleeder Bonnet in Valve Assemblies?

In many industrial valve systems, maintenance engineers often face a recurring issue — residual pressure trapped inside the valve cavity even after shut-off. This hidden pressure can lead to serious safety hazards and costly downtime if not properly vented. To solve this, engineers use a specialized component known as a bleeder bonnet, designed to safely […]

Types of Grease Fittings and Their Functions

In many industrial and mechanical systems, insufficient lubrication leads to premature bearing wear, downtime, and high maintenance costs. Yet many engineers and maintenance teams overlook one simple but critical factor — the type of grease fitting used. Without the right fitting, grease cannot reach friction points efficiently, resulting in wasted lubricant and equipment failure. Selecting […]