What is a check valve and how does it control flow direction?

A check valve is a one-way valve that allows fluid (gas or liquid) to flow in only one direction, automatically preventing reverse flow through a mechanical mechanism like a disc, ball, or poppet.

Why This Question Matters in Industrial Fluid Systems

In B2B industrial environments—such as oil and gas pipelines, chemical processing lines, and high-pressure hydraulic systems—controlling the direction of flow is not just about efficiency, but about safety, equipment longevity, and process reliability.

Imagine a situation where reverse flow causes contamination in an ultra-clean instrumentation line or backpressure damages expensive compressors. That’s where check valves come in.

At Walter Valves, we manufacture and supply high-precision check valves for global industrial buyers across sectors. Our customers from the Middle East to Europe often ask the same question: How do check valves actually control flow direction, and how do I choose the right one for my application?

What Is a Check Valve and How Does It Control Flow Direction?

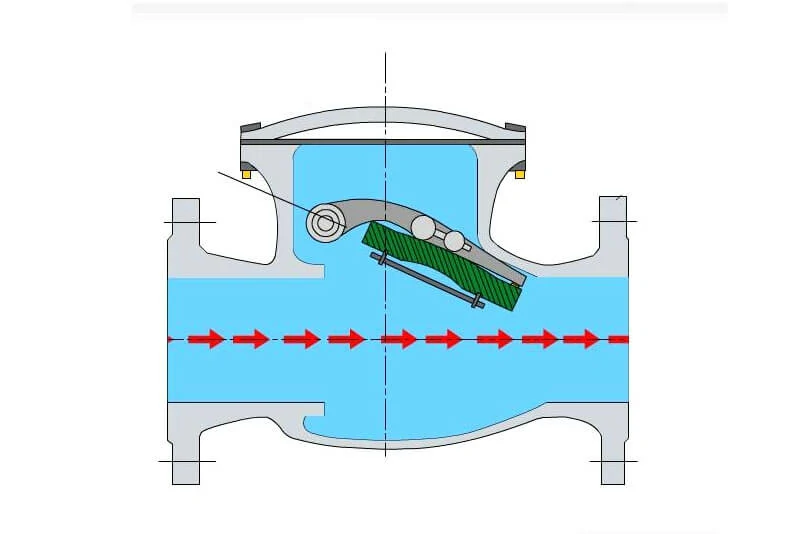

A check valve is a passive, self-actuating valve designed to allow fluid to flow in one direction and automatically block it from flowing in the opposite direction. It uses internal components such as swing discs, lift poppets, or spring-loaded balls that respond to pressure changes in the pipeline.

There’s no need for external actuation or human intervention—check valves operate based purely on flow dynamics. Once forward flow starts and pressure exceeds the cracking pressure, the valve opens. When reverse flow or backpressure occurs, the valve shuts automatically.

Why Use Check Valves for Flow Direction Control?

Preventing Backflow and Contamination

Check valves are essential for protecting upstream equipment from backpressure, particularly in systems carrying hazardous or sensitive media like gases, hydraulic oil, or corrosive chemicals.

Ensuring Process Integrity

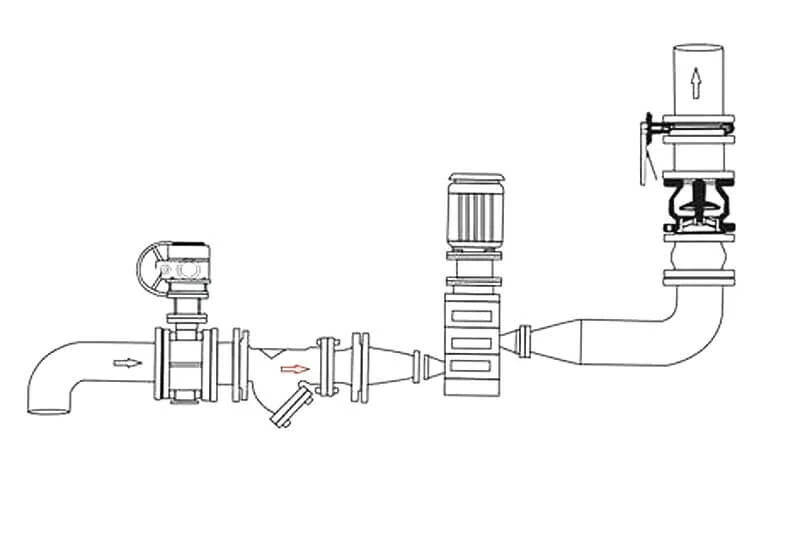

Whether in a metering system, chemical injection skids, or control panels, maintaining unidirectional flow ensures accurate measurements and safe performance.

Avoiding Equipment Damage

Reverse flow can cause damage to pumps, filters, and meters. For example, sudden backpressure in hydraulic systems can rupture seals or damage instruments—check valves prevent this automatically.

Eliminating the Need for Manual Monitoring

Because they operate without electrical or pneumatic actuators, check valves reduce control complexity and power consumption.

What are the different types of check valves?

There are several designs of check valves used in industrial applications:

| Type of Check Valve | Mechanism | Common Use |

| Ball Check Valve | Uses a spring-loaded ball to seal flow in reverse direction | Instrumentation, fuel lines |

| Swing Check Valve | Uses a swinging disc to block reverse flow | Water & wastewater |

| Lift Check Valve | Flow lifts the disc or piston vertically; gravity or spring shuts it | Vertical lines, low flow |

| Poppet Check Valve | Piston-shaped plug moves within a guide | High-pressure systems |

| Diaphragm Check Valve | Rubber diaphragm flexes under pressure | Chemical systems, low-pressure |

For precision control, Walter Valves offers spring-loaded instrumentation check valves that crack open at specific pressures—critical in gas sampling and pressure test lines.

How do you determine flow direction in a check valve?

Most check valves have a directional arrow engraved or marked on the valve body to indicate the proper flow path. Flow should always enter from the inlet side and exit through the outlet. Installing the valve backwards prevents it from opening and blocks fluid movement altogether.

Additionally, consider:

Cracking Pressure: The minimum upstream pressure required to open the valve.

Mounting Orientation: Some valves (like swing types) may not perform well in vertical pipelines unless specifically designed.

What is cracking pressure and why is it important?

Cracking pressure is the pressure at which a check valve starts to open and allow forward flow. This is crucial for low-pressure systems or sensitive instrumentation. If cracking pressure is too high, the valve may remain shut, disrupting flow.

At Walter Valves, our check valves are available with various cracking pressures (e.g., 1/3 PSI to 25 PSI) tailored to different instrumentation systems.

Where are check valves used?

Check valves are found in a wide range of industrial applications:

Oil & Gas Pipelines – To prevent reverse flow during compressor shutdowns.

Hydraulic Systems – To isolate actuators and prevent backflow pressure buildup.

Water Treatment Plants – To prevent contamination of clean water lines.

Pneumatic Systems – To maintain air flow direction without manual control.

Chemical Injection Panels – To avoid back-mixing of reactive agents.

How to Choose the Right Check Valve for Flow Control?

When sourcing check valves, consider the following technical criteria:

1. Media Compatibility

Choose body and seal materials compatible with your working fluid. Walter Valves offers stainless steel, brass, and alloy check valves with PTFE, Viton®, and EPDM seals.

2. Flow Characteristics & Cv

Look at the flow coefficient (Cv) to determine how much resistance the valve adds to your system. Lower Cv = more restriction.

3. Operating Pressure & Temperature

Make sure your valve can withstand your maximum working pressure and temperature. Our high-performance check valves handle up to 6,000 psi and 200°C.

4. Cracking Pressure

Select based on system sensitivity. Lower cracking pressure is ideal for low-pressure gas lines.

5. Size & End Connections

Walter Valves provides multiple sizes (1/8″–2″) and threads (NPT, BSP, compression fittings) for flexible installation.

Tips for Installation and Maintenance

Install in the correct direction — follow the arrow.

Ensure system is clean — debris can prevent proper sealing.

Avoid water hammer — rapid closing can cause shockwaves in the system.

Check periodically — worn seats or fouled springs can lead to leakage.

At Walter Valves, we recommend periodic inspection, especially in critical systems like chemical dosing or fuel lines. Our check valves are designed for easy replacement and minimal maintenance.

Conclusion

Check valves play a silent but essential role in maintaining flow direction, preventing backflow, and protecting sensitive instrumentation and equipment. Choosing the right check valve for your system ensures long-term reliability, safety, and performance.

At Walter Valves, we specialize in high-precision instrumentation valves including check valves, ball valves, needle valves, and more. With factory-direct pricing, short delivery times, and global export experience, we’re trusted by industrial buyers across six continents.

Ready to Upgrade Your Flow Control System?

Email us at info@waltervalves.com for a free technical consultation or request a custom quote.

Ask about our bulk order discounts and short lead time inventory for international buyers.