Visión general

La válvula de doble bloqueo y purga (DBB) de Water Valves ofrece una solución compacta y de alta integridad para el aislamiento y purga críticos en sistemas de alta presión. Diseñadas para sustituir a los complejos conjuntos multiválvula, nuestras válvulas DBB integran dos válvulas de aislamiento y una válvula de purga en un solo cuerpo, lo que ahorra espacio y peso y reduce las posibles vías de fuga. Ideales para plataformas petrolíferas y de gas, petroquímicas y marinas.

Características del producto:

Doble aislamiento + función de purga central

Cuerpo compacto de una sola pieza forjado o en barra

Disponible en combinaciones bola/bola, aguja/aguja o aguja/bola

Diseño del vástago a prueba de reventones

Diseño ignífugo y antiestático (conforme a API 607)

Adecuado para instalación horizontal o vertical

Disponibles con conexiones finales embridadas, roscadas o soldadas

Categorías

Características

- Presión máxima de trabajo: 690 bar (10.000 psig)

- Diseño especial para permitir que el lubricante o sellador fluya alrededor del muelle y a través de la abertura en los lados de

el retenedor suavemente - Construcción totalmente metálica, aplicable en entornos de alta y baja temperatura

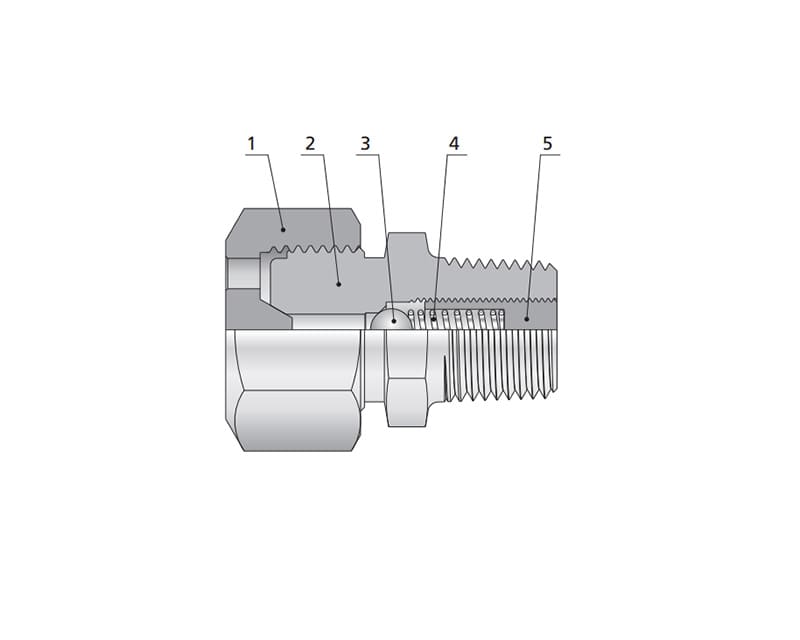

Componente

No. | Componente | Acero al carbono | SS 316 |

|---|---|---|---|

1 | Tapa de ventilación | CS (Zinc) | SS 316/A479 |

2 | Cuerpo | CS (Zinc) | SS 316/A479 |

3 | Bola | 316/A276 | Carburo de tungsteno |

4 | Primavera | X-750/AMS 5699 | X-750/AMS 5699 |

5 | Retenedor | SS 316/A479 | SS 316/A479 |

Datos técnicos

Consideraciones al comprar engrasadores

Conexiones finales

NPT 1/4″, 3/8″, 1/2″, 3/4″, 1″

GAS 3/8″, 1/2

Presión de trabajo

Presión de trabajo hasta: 690 bar (10.000 psig)

Material disponible

A105 LF2

Acero inoxidable 304 Acero inoxidable 316L

Aleación 400 Aleación 625 Aleación C-276

Dúplex 2205 Dúplex 2207

NOTAS: otros productos o diferentes diseños de herrajes disponibles bajo pedido; todas las medidas están en milímetros.

Benefíciese del compromiso de su fabricante de válvulas y accesorios

Muestra gratuita de herrajes

Walter le ofrece una muestra de ajuste gratuita para que la pruebe y confirme que cumplimos los requisitos de su diseño personalizado.

Precio al por mayor de accesorios

Nuestros accesorios de alta calidad están disponibles a precios al por mayor, lo que le permite ahorrar dinero y reducir sus costes de producción.

Baja cantidad mínima de pedido

Todos nuestros clientes son importantes para nosotros y por ello nuestro MOQ es de 10 piezas para dar cabida a pedidos grandes y pequeños.

Botella de alta calidad

Somos meticulosos con nuestros controles de calidad y normas de fabricación. Nuestro objetivo es ofrecerle las mejores botellas de vidrio.

Servicios posventa sin preocupaciones

El equipo de Walter está siempre a su disposición para guiarle en los procedimientos posventa, como el almacenamiento, el envío y la entrega "justo a tiempo".

PREGUNTAS FRECUENTES

R: Una válvula de doble bloqueo y purga (DBB) combina dos válvulas de aislamiento y una válvula de purga en un único cuerpo compacto. Garantiza el aislamiento completo de los medios de proceso para el mantenimiento, el alivio de presión o las comprobaciones de seguridad, al tiempo que minimiza el riesgo de fugas de las líneas aguas arriba.

R: Ofrecemos múltiples configuraciones, incluidas las combinaciones bola-bola, aguja-aguja y aguja-bola. La selección depende de la clase de presión de la aplicación, el caudal y los requisitos de control.

R: Las válvulas DBB se utilizan ampliamente en los sectores del petróleo y el gas, la petroquímica, el procesamiento químico, la generación de energía y la perforación en alta mar, especialmente para el aislamiento de transmisores de presión, la inyección de productos químicos y el mantenimiento de tuberías.

R: Sí. Nuestras válvulas DBB están disponibles con extremos roscados (NPT/BSP), embridados (ASME B16.5), de soldadura por encastre o de soldadura a tope. También se admiten tipos de conexiones finales personalizadas bajo pedido.

R: Todas las válvulas se someten a las pruebas hidrostáticas y de fugas de asiento 100% según API 598. También ofrecemos certificación de seguridad contra incendios (API 607), conformidad con NACE MR0175, marcado CE e inspección por terceros si es necesario.

¿Está listo para obtener soluciones de válvulas fiables?

En Water Valves, somos especialistas en válvulas y accesorios diseñados con precisión para funcionar en los sectores más exigentes del mundo. Tanto si necesita componentes estándar como soluciones personalizadas, nuestro equipo está aquí para atender las necesidades de su proyecto.