A double block and bleed (DBB) valve is a critical safety component in piping systems that provides isolation and leakage prevention for hazardous fluid processes. This comprehensive guide explains how a double block and bleed valve works, its key components, and why it’s essential for oil/gas, chemical, and other high-risk industries.

Whether you need to understand how a double block and bleed valve works in specific applications or compare different types, this article covers all aspects of DBB valve functionality. Read on to discover the operational principles, industry standards, and best practices for implementing DBB valves in your systems.

What is the Difference Between Block and Bleed and Double Block and Bleed Valves?

The distinction between block and bleed versus double block and bleed (DBB) systems represents a fundamental difference in safety philosophy for fluid isolation.

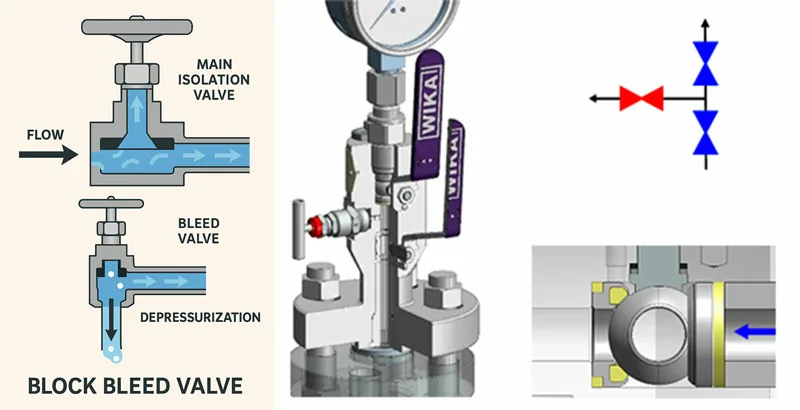

A standard block and bleed configuration provides basic isolation through a single valve combined with a bleed port, creating one barrier against process fluid while allowing for downstream depressurization. This simpler arrangement may suffice for non-critical applications with low-risk media.

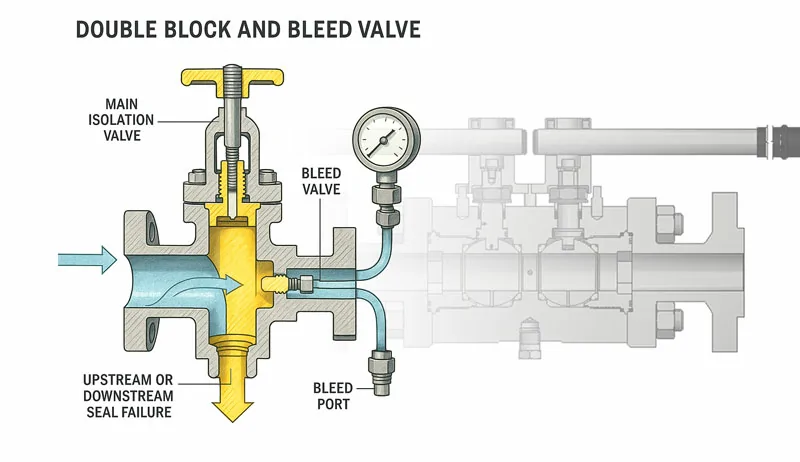

However, the double block and bleed system elevates this concept to a higher safety standard by incorporating two completely independent isolation valves in series, with a shared bleed valve positioned strategically between them. This design creates two positive barriers that can each independently contain full system pressure from either direction, effectively providing a backup seal should one valve fail.

The API 6D standard specifically defines DBB valves as having two distinct seating surfaces that each must provide a reliable seal against pressure from both valve ends when in the closed position. This dual-seal requirement fundamentally changes the safety profile of the system — while a single block and bleed relies on one valve’s integrity, the DBB system maintains protection even if one seal were to develop a leak.

The intermediate bleed port serves multiple critical functions: it allows for pressure monitoring between the seals to verify their integrity, provides a safe means to drain any trapped fluid, and prevents potentially dangerous pressure buildup in the cavity between the two block valves. This comprehensive approach makes DBB valves particularly valuable for hazardous, flammable, or environmentally sensitive applications where absolute containment is non-negotiable.

How Does a Bleed Valve Work in a DBB System?

The bleed valve in a double block and bleed assembly serves as the system’s diagnostic heart and safety sentinel. Positioned between the two primary isolation valves, this component transforms what would otherwise be just two valves in series into an intelligent, verifiable isolation system.

Its primary function as a monitoring point allows operators to positively confirm the integrity of both sealing barriers — when opened, any fluid or pressure detected at the bleed port indicates potential leakage across one or both block valves. This verification capability is crucial during maintenance operations where absolute isolation must be confirmed before work begins.

Beyond its diagnostic role, the bleed valve performs essential pressure management functions. It safely relieves any thermal expansion of trapped fluid between the dual seals that could otherwise create dangerous pressure buildup. During maintenance procedures, it enables complete depressurization and drainage of the inter-seal cavity.

The bleed valve also serves as a sampling point for fluid analysis when checking for cross-contamination between systems. Proper operational sequencing is critical — technicians should first close the upstream isolation valve, verify its seal integrity through the bleed port, and only then close the downstream valve. This methodical approach provides positive confirmation of each seal’s performance in sequence.

When is Double Block and Bleed Required in Industrial Applications?

Double block and bleed valves have become the gold standard for isolation in numerous high-risk industrial scenarios due to their unmatched safety profile.

In oil and gas operations, DBB systems are mandatory for critical applications including wellhead isolation, pipeline maintenance sections, and storage tank protection systems. The chemical processing industry relies on DBB technology when handling corrosive or highly toxic fluids where even minor leakage could have catastrophic consequences.

Power generation facilities implement DBB valves for steam line isolation in boilers and turbines, where high temperatures and pressures demand fail-safe protection.

Refineries extensively use DBB configurations at hydrocarbon transfer points and for relief valve isolation, where their positive seal verification prevents dangerous releases.

Industry standards like API 6D, ISO 14313, and ASME B16.34 specifically mandate DBB use for certain pressure classes and fluid services, particularly in hydrocarbon systems. Many operators now adopt DBB as a best practice even beyond regulatory requirements, recognizing that the additional safety margin justifies the incremental cost.

The growing emphasis on process safety management and environmental protection continues to drive expanded use of DBB technology across industrial sectors.

What Are the Different Types of Double Block and Bleed Valves?

The industrial market offers several specialized configurations of double block and bleed (DBB) valves, each designed to meet specific operational requirements.

The most prevalent type utilizes a dual ball valve arrangement with an integrated bleed port, featuring trunnion-mounted balls that provide reliable sealing under high pressures. These ball valve systems are particularly valued for their quarter-turn operation that enables rapid isolation, with full-port designs maintaining excellent flow characteristics and minimizing pressure drops.

For extreme temperature applications exceeding 400°F, metal-seated versions are available where conventional soft seats would fail, while advanced stem sealing technologies prevent external leakage across various operating conditions.

For handling challenging media such as slurries, viscous fluids, or particulate-laden streams, plug valve-based DBB systems demonstrate superior performance. These specialized valves incorporate wedge-shaped plugs that actively shear through accumulated deposits during operation, preventing the buildup that could jam other valve types.

The lubricated versions use specialized sealants that simultaneously reduce operating torque and create positive sealing against sticky process media, while their top-entry construction allows for simplified maintenance without requiring complete valve removal from the pipeline.

Beyond these primary configurations, industrial applications employ various specialized DBB solutions tailored to specific operational needs. Gate valve assemblies are preferred for high-pressure steam services where their robust construction withstands extreme thermal cycling, while needle valve configurations provide precise flow control in instrumentation systems requiring accurate regulation. Compact integral manifolds offer space-efficient solutions for instrument isolation scenarios with footprint constraints.

Each variant maintains the fundamental DBB safety philosophy while addressing unique service environment demands through specialized engineering.

Key Selection Criteria for DBB Valves

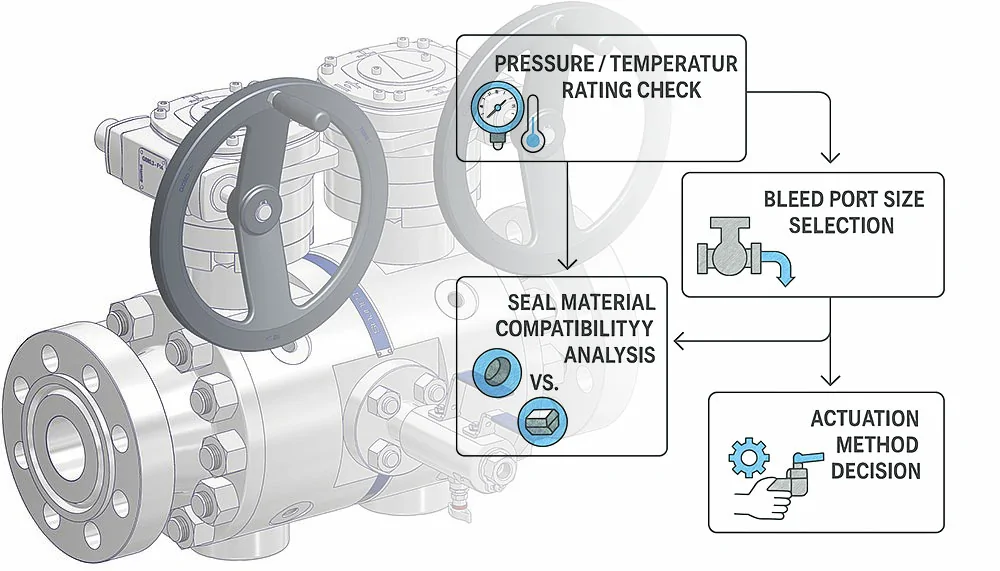

Selecting the appropriate double block and bleed valve requires careful evaluation of multiple technical parameters to ensure optimal performance and safety.

Engineers must thoroughly assess pressure and temperature ratings to confirm compatibility with process conditions, as exceeding these limits could compromise valve integrity. The selection of seal materials demands particular attention, requiring compatibility analysis with fluid properties — elastomer seals may suffice for general services, while corrosive or high-temperature applications typically necessitate metal seals.

The bleed port design warrants special consideration to ensure adequate drainage capacity, with undersized ports potentially leading to incomplete depressurization or slow response times.

Industry certifications serve as critical selection criteria, with API 607/6FA certification essential for fire-safe performance in hydrocarbon services and NACE MR0175 compliance required for sour service applications containing H₂S.

Actuation methodology should reflect both operational frequency and accessibility considerations — manual operation may suffice for infrequently used valves, while pneumatic or hydraulic actuation becomes necessary for remote or frequently cycled applications.

Additional factors include material compatibility with process fluids, connection types matching existing piping, and compliance with relevant industry standards like API 6D for pipeline applications.

This comprehensive evaluation process ensures the selected DBB configuration delivers reliable performance while meeting all safety and regulatory obligations, ultimately preventing costly failures and downtime.

Conclusion

Double block and bleed valves provide unmatched isolation reliability by combining two positive seals with diagnostic bleed capability. Their design fundamentally prevents single-point failures that could release hazardous process fluids during maintenance or emergencies.

For operations handling flammable, toxic, or high-pressure media, DBB valves are increasingly becoming the isolation method of choice — either as standalone valves or integrated into manifold systems.

Need expert guidance on DBB valve selection?

Our engineering team specializes in matching valve configurations to your specific process requirements. Browse our DBB product line or contact us for a customized consultation on implementing these critical safety devices in your facility.

Upgrade your isolation strategy today with API-compliant double block and bleed solutions that deliver proven leakage protection.