An instrumentation ball valve is a specialized flow control device designed for precise regulation and isolation in analytical, measurement, and control systems. These compact, high-performance valves are essential components in process instrumentation, providing reliable shut-off for gases and liquids in pressure measurement, sampling, and chromatographic applications.

Understanding the features of premium products like Parker instrumentation ball valve systems and Swagelok one-piece instrumentation ball valves is crucial for engineers and technicians working with critical process instrumentation. This comprehensive guide explores the design principles, functionality, and selection criteria for instrumentation ball valves, providing essential knowledge for optimizing your process control systems.

What Is an Instrumentation Ball Valve?

An instrumentation ball valve is a compact, precision-engineered valve designed specifically for use in instrument piping and process control systems. Unlike standard industrial ball valves, instrumentation versions feature reduced bore sizes, typically ranging from 1/8″ to 1/2″, and are engineered for exceptional leak-tight performance and cycle life.

These valves utilize a rotating ball with a precision-machined bore that aligns with the flow path in the open position and rotates 90 degrees to block flow in the closed position. The design incorporates high-quality stem seals and ball surfaces that ensure bubble-tight shutoff, even after thousands of operating cycles.

Instrumentation ball valves are characterized by their compact dimensions, standardized end connections suitable for tube fitting installation, and materials compatible with a wide range of process media.

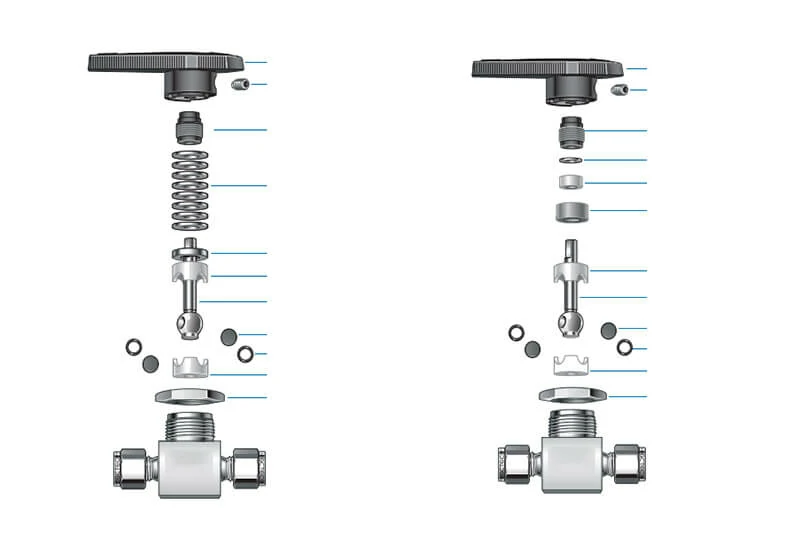

They are available in various configurations including one-piece, two-piece, and three-piece designs, each offering different maintenance and performance characteristics. The one-piece design provides maximum integrity for critical applications, while three-piece designs allow for easy maintenance and cleaning without removing the valve from the pipeline.

These valves are manufactured to stringent quality standards using materials such as 316 stainless steel, brass, and specialty alloys to withstand corrosive environments and maintain performance in demanding applications.

What Is the Purpose of Instrumentation Valves in Industrial Systems?

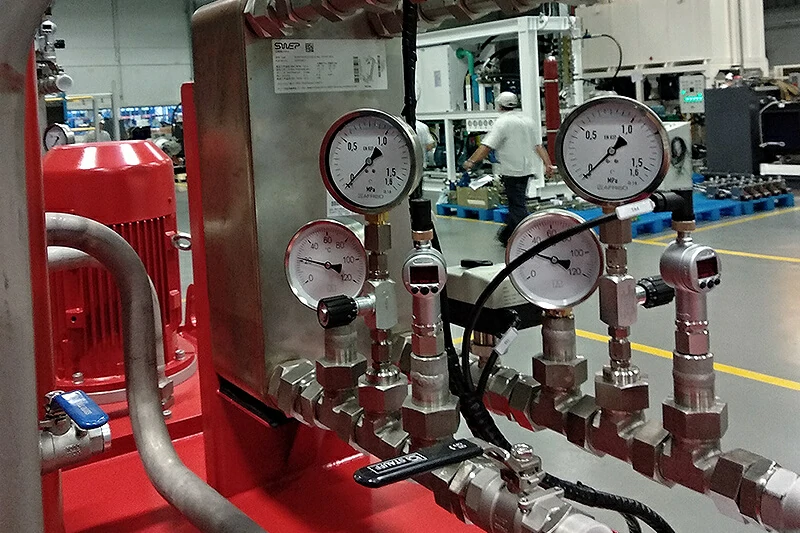

Instrumentation valves serve critical functions in industrial measurement and control systems by providing precise flow management for analytical instruments, pressure gauges, and sampling systems.

Their primary purpose is to ensure reliable isolation of instrumentation from process media, allowing for safe maintenance, calibration, and replacement of measuring devices without system shutdown.

In pressure measurement applications, they enable isolation of pressure transmitters and gauges, while in analytical systems they facilitate sample collection and injection without process contamination.

These valves protect sensitive instrumentation from process media during abnormal conditions and provide means for zero calibration and span checking of instruments. In chromatographic systems, instrumentation valves enable precise sample introduction and column switching.

Their compact size allows for installation in confined spaces within instrument panels and analyzer shelters. The reliability of instrumentation valves directly impacts measurement accuracy and system safety, making proper valve selection and installation crucial for overall system performance.

They also provide emergency isolation capabilities that can prevent hazardous material release during instrument failure or maintenance activities, contributing significantly to plant safety and environmental protection.

What Is the Function of a Ball Valve Compared to Other Valve Types?

Instrumentation ball valves provide several distinct functional advantages compared to other valve types commonly used in instrument systems.

Unlike needle valves that offer fine flow control but limited shutoff capability, ball valves provide positive shutoff with minimal pressure drop when fully open.

Compared to plug valves, ball valves typically offer lower operating torque and better sealing characteristics, especially in smaller sizes common in instrumentation applications. Their quarter-turn operation allows for quick opening and closing, which is particularly valuable in emergency shutdown situations or when rapid isolation is required.

The full bore design available in many instrumentation ball valves minimizes pressure drop and prevents media entrapment that could affect measurement accuracy. This contrasts with globe valves that inherently create significant pressure drop due to their flow path design.

Ball valves also outperform gate valves in instrumentation applications due to their compact size, faster operation, and superior sealing capabilities in clean service applications.

For sampling systems, ball valves provide quicker response than needle valves while still offering adequate control for most applications. Their simple design with minimal internal cavities reduces areas where media could be trapped, making them suitable for applications requiring high purity or cleanability.

The versatility of ball valves allows them to handle a wide range of media including gases, liquids, and some slurries, provided the valve materials are compatible with the process media.

What Are the Pressure Ratings of Instrumentation Valves?

Instrumentation ball valves are available with pressure ratings designed to meet various application requirements, typically ranging from vacuum service to high-pressure applications exceeding 10,000 psi.

Standard instrumentation ball valves commonly feature pressure ratings of 1,000 to 6,000 psi for general industrial applications, with specialized high-pressure designs available for exceptional requirements.

The pressure rating depends on several factors including valve body material, ball and stem design, seal materials, and manufacturing quality. Stainless steel valves typically offer higher pressure ratings than brass versions, with forged bodies providing superior strength compared to bar stock designs.

Temperature considerations affect pressure ratings, with most manufacturers providing derating information for elevated temperature service.

End connection types significantly influence pressure capability, with face seal connections generally providing higher pressure ratings than threaded connections. Manufacturers like Parker and Swagelok provide detailed pressure-temperature ratings for their instrumentation ball valves, ensuring proper selection for specific service conditions.

It’s crucial to consider not only the maximum operating pressure but also pressure shock and cycling requirements, as these factors can affect valve selection. Proper installation and torque application during fitting make-up also impact the achieved pressure capability of the installed valve system.

Understanding these rating systems ensures selection of valves that will perform reliably under expected operating conditions while providing appropriate safety margins.

How Do You Select Instrumentation Valves and Accessories?

Selecting the appropriate instrumentation valves requires careful consideration of multiple factors to ensure optimal performance and reliability.

The process begins with understanding the application requirements including media type, pressure and temperature ranges, flow characteristics, and cycle frequency.

Material compatibility is paramount, with valve body, ball, stem, and seal materials selected based on chemical compatibility with the process media. End connections must match existing tubing or pipe systems, with considerations for pressure capability and ease of installation.

Operational requirements dictate choices between manual, pneumatic, or electric actuation based on accessibility, frequency of operation, and automation needs. For sampling applications, volume displacement and dead space considerations may favor specific valve types.

Maintenance requirements should influence selection, with three-piece designs offering easier maintenance access compared to one-piece versions. Industry standards and certifications such as ISO 9001, ASME B16.34, and pressure equipment directives may dictate certain design features or documentation requirements.

Manufacturer reputation and product support should be considered, including availability of technical data, lead times, and local support capabilities. Economic factors include not only initial purchase price but also total cost of ownership considering maintenance requirements, expected service life, and potential impact on system performance.

Proper selection requires balancing these factors to achieve the optimal combination of performance, reliability, and cost-effectiveness for the specific application.

結論

Instrumentation ball valves play a critical role in ensuring the accuracy, reliability, and safety of process measurement and control systems. Their compact design, excellent sealing capabilities, and versatile operation make them ideal for a wide range of applications from pressure measurement to analytical sampling.

Understanding the differences between instrumentation ball valves and other valve types, along with their pressure capabilities and selection criteria, is essential for designing and maintaining effective instrument systems.

The choice between different valve configurations, materials, and end connections should be based on comprehensive analysis of application requirements rather than default selections.

Properly selected and installed instrumentation valves contribute significantly to system accuracy, reduce maintenance requirements, and enhance overall process safety. As process instrumentation becomes increasingly sophisticated, the importance of high-performance valves that can maintain measurement integrity continues to grow.

For assistance with instrumentation valve selection or technical support, contact our engineering team for expert guidance tailored to your specific application requirements.

Explore our comprehensive product range featuring industry-leading brands and innovative valve solutions. Request a consultation to discuss your project needs and discover how our instrumentation valves can enhance your system performance and reliability.

Choose us as your partner for quality instrumentation components and technical support that ensures your measurement systems operate at their optimal potential.