グリース継手ゼルクまたはグリースニップルとしても知られるこの部品は、可動部品の効率的な潤滑を可能にするため、機械や装置で使用される小さいながらも重要な部品です。これらは、ベアリング、ジョイント、および他の摩擦が発生しやすい領域に直接潤滑剤を供給するためのグリースガンのための標準化されたポイントを提供します。この記事では、グリース・フィッティングとは何か、どのように機能するのか、利用可能なさまざまなタイプ、および業界全体にわたるその用途について説明します。グリース・フィッティングは、機械部品に潤滑油を注入できるように設計された小さな機械的コネクターです。摩擦を減らし、磨耗を防ぎ、スムーズな作動を保証するために、自動車、産業機器、農業機器に一般的に使用されています。

グリース・フィッティングがどのように機能するのか、利用可能なさまざまなタイプ、そして取り付けと使用のベスト・プラクティスについて、詳しくお読みください。

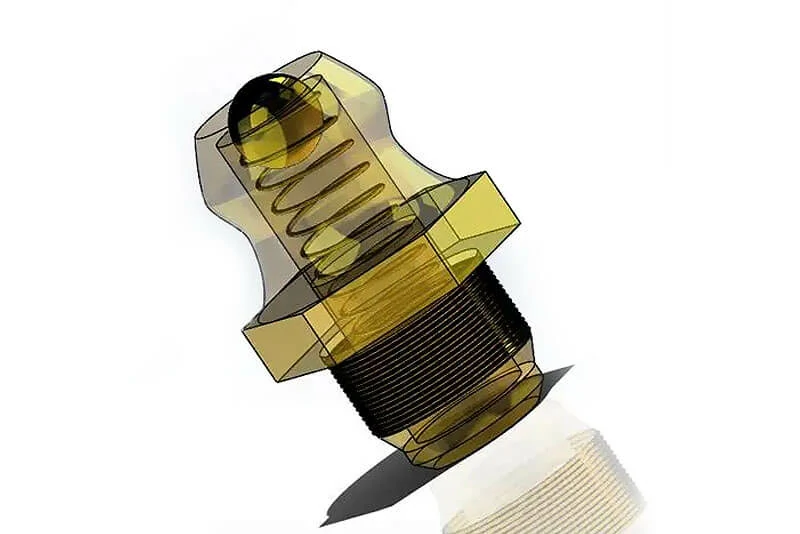

グリース・フィッティングの仕組み

グリース・フィッティングは、ベアリングやピボット・ジョイントなど、機械の特定の部分に潤滑剤が入るための密閉された通路を提供することによって機能する。継手には小さなバネ仕掛けのボールがあり、使用していないときは開口部を密閉している。グリースガンを取り付けて圧力をかけると、ボールが内側に押され、グリースが部品に流れ込みます。グリースガンを取り外すと、ボールは元の位置に戻り、汚染物質の侵入や潤滑油の流出を防ぎます。このシンプルかつ効果的なメカニズムにより、潤滑はクリーンで、コントロールされ、効率的に行われます。

グリース・フィッティングの種類とは?

グリース継手にはいくつかの一般的なタイプがあり、それぞれ特定の用途と圧力要件に合わせて設計されています。ストレートタイプのグリース継手は最も広く使用されているタイプで、一般的な用途に適しています。フラッシュタイプのグリース継手は、継手が突出してはならない用途で使用され、損傷のリスクを低減します。ボタンヘッド式継手は高圧用途に最適で、ドライブ式継手はあらかじめ開けられた穴に打ち込んで取り付けます。各タイプは、異なる機械的・環境的条件に適した独自の特徴を持っています。

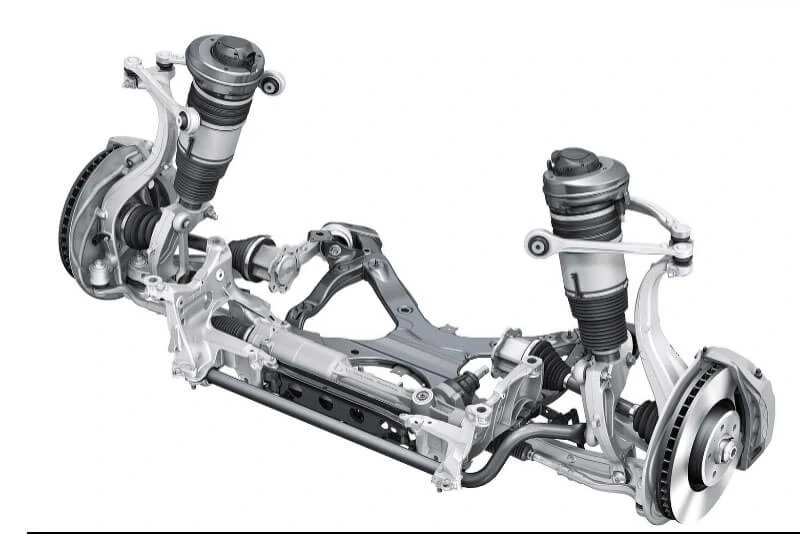

グリース継手はどこで使われるのか?

グリース継手は、可動部品が定期的な潤滑を必要とする幅広い産業や用途で使用されています。自動車業界では、サスペンション・システム、ステアリング・リンケージ、ブレーキ部品に使用されています。コンベヤーシステム、ポンプ、モーターなどの産業機械では、信頼性の高い動作を保証するためにグリース継手が組み込まれていることがよくあります。トラクターや収穫機を含む農業機械は、埃っぽく高負荷の条件に耐えるためにグリース継手に依存しています。さらに、定期的な潤滑が必要な建設機械、船舶、家庭用電化製品にも使用されています。

グリース・ゼルクの目的は?

グリース・ゼルクは、グリース・フィッティングの別名であり、潤滑機器に便利で安全な接続ポイントを提供するという目的を果たす。ザーク」という用語は、発明者であるオスカー・ザークの名前に由来しており、多くの産業でグリース継手の代名詞となっている。ゼルクの主な目的は、機械を分解することなく潤滑油を注入できるようにし、時間を節約してダウンタイムを減らすことである。また、汚れやゴミがシステムに入るのを防ぎ、潤滑プロセスをクリーンに保つのにも役立ちます。

グリース・フィッティングの見分け方

グリース・フィッティングを識別するには、その物理的特性とねじの仕様を認識する必要があります。ほとんどのグリース・フィッティングは、レンチを使って簡単に取り付けたり外したりできるように、六角形のベースを持っています。先端はグリースガンのノズルに対応するように設計されており、直線状、角度付き、またはボタン状の場合があります。一般的なネジ規格には、SAE(インペリアル)とメトリックがあります。ノギスやスレッドゲージでネジの直径とピッチを測定することで、交換や取り付けに必要なフィッティングの正確なタイプを判断することができます。

メートル対SAEのグリース継手:その違いは?

メートルとSAEのグリース継手の主な違いは、そのスレッド測定にあります。SAE継手はインペリアル単位を使用し、ねじのサイズはインチで表され、メートル継手はミリメートルを使用しています。この違いは、特定の地域や産業向けに設計された機器との互換性に影響を与えます。例えば、米国で製造された機械はSAE継手を使用することが多いが、欧州で製造された機器は一般的にメートルネジを使用する。ねじの交差、漏れ、機器の損傷を避けるためには、正しいねじのタイプを使用することが不可欠です。必要に応じて、これらのシステム間のギャップを埋めるためにアダプターをご利用いただけます。

グリース・フィッティングの正しい取り付け方?

グリース・フィッティングを正しく取り付けることは、効果的な潤滑を確保し、漏れを防ぐために非常に重要です。まず、ネジ穴を十分に清掃し、汚れ、古いグリース、破片を取り除きます。フィッティングにスレッド・シーラントを塗布し、しっかりとシールして漏れを防ぎます。レンチを使用してフィッティングをしっかりと締めますが、ネジ山を剥がしたり、フィッティングを損傷させたりする可能性のある締めすぎは避けてください。圧入フィッティングの場合、穴のサイズが適切であることを確認し、ハンマーまたはアーバー・プレスを使用してフィッティングを均等に取り付けます。トルク値や取り付けのガイドラインについては、常にメーカーの仕様書を参照してください。

重機に最適なグリース継手?

重機には、高圧、振動、過酷な環境に耐える耐久性と信頼性の高いグリース継手が必要です。ボタンヘッド継手は、しばしば漏れすることなく高圧潤滑を処理する能力のために好まれています。ステンレス鋼継手は、海洋や化学産業などの腐食性環境に最適です。大規模な建設機械や鉱山機械では、強化された設計と頑丈な継手は、長期的な性能を提供します。運転条件に基づいて適切な材料、サイズ、およびタイプの継手を選択することは、機器の効率を維持し、メンテナンスコストを削減するために不可欠です。

Waltervalvesがグリース継手の信頼できるサプライヤーである理由?

Waltervalvesは、耐久性と性能の国際基準を満たす製品を提供することにより、高品質のグリース継手の信頼できるサプライヤーとしての評判を築いてきました。同社の継手は、鋼、ステンレス鋼、真鍮などの堅牢な材料から製造され、様々な用途との互換性を保証します。Waltervalvesは、専門的な技術サポートとともに、SAE、メートル、および特殊継手を含む幅広いタイプとサイズを提供しています。顧客満足と信頼性の高いデリバリーへのコミットメントにより、同社は世界中の産業界に好まれるパートナーとなっています。

結論

グリース・フィッティングは小さなものかもしれませんが、数え切れないほど多くの産業において、機械の性能と寿命を維持するために重要な役割を果たしています。どのように機能するのか、どのような種類があるのか、どのように正しく取り付けるのかを理解することで、機器の故障を防ぎ、メンテナンスコストを削減することができます。高品質のグリース・フィッティングをお探しなら、以下をご検討ください。 ウォルターバルブス は、信頼性の高い製品と専門的なサポートを提供するサプライヤーです。同社のウェブサイトをご覧いただくか、今すぐ同社のチームにご連絡ください。