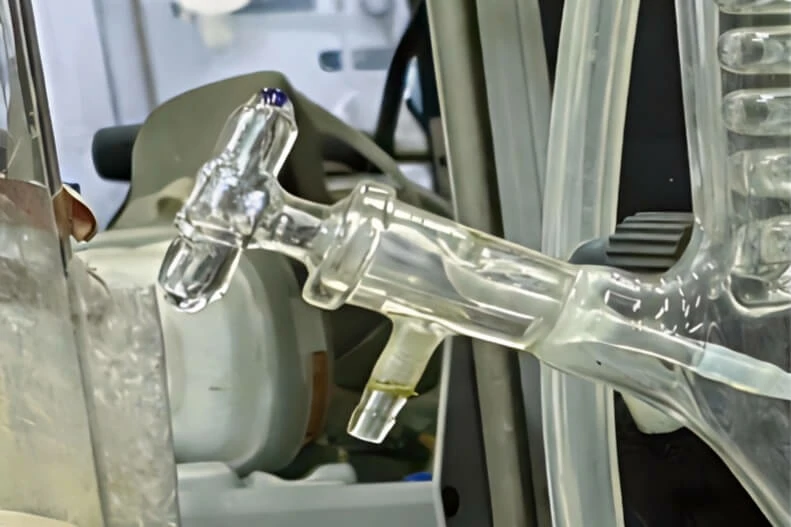

ブリーダーボンネットの取り付けとメンテナンス方法

加圧配管システムにおいて、オペレーターはしばしば、ブリーダー・ボンネットの適切な取り付け方とメンテナンス方法に悩まされます。この小さな部品にミスがあると、危険な圧力保持、漏れ、機器の故障につながる可能性があります。そのため、ブリーダー・ボンネットの正しい取り付け方と定期的なメンテナンスを理解することは、職場の安全性とシステムの信頼性を確保するために不可欠です。このガイドでは、ブリーダー・ボンネットの適切な取り付けと保守について、ステップ・バイ・ステップの手順と専門家のヒントをご紹介します。ブリーダーボンネットは、バルブシステムに取り付けられ、閉じ込められたガスや液体を手動で排出する小型の圧力開放装置です。正しく取り付け、定期的に点検することで、漏れや圧力の上昇、コストのかかるダウンタイムを防ぐことができます。完全な保護と性能のために、設置手順、メンテナンス方法、一般的なトラブルシューティングのヒントについて読み進めてください。[...]

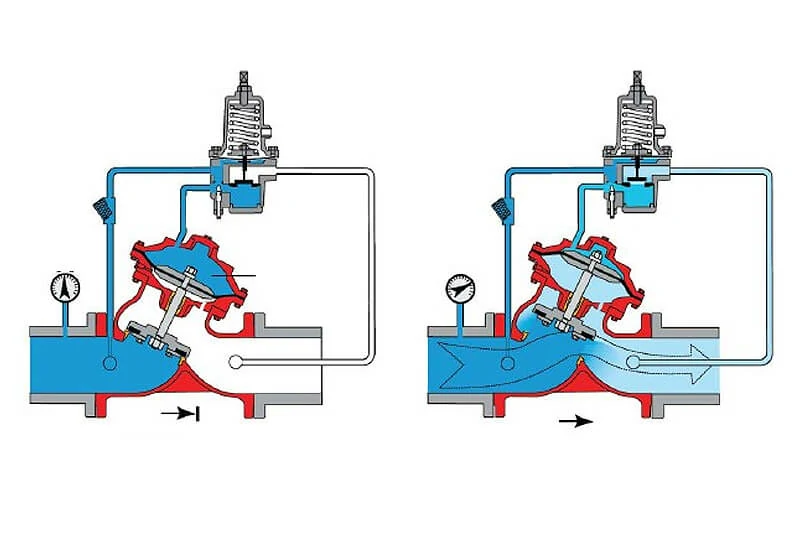

リリーフバルブの仕組み

高圧産業システムでは、突然の圧力スパイクが機器の致命的な故障、安全上の危険、コストのかかるダウンタイムにつながる可能性があります。多くのエンジニアや購買マネージャーは、これらのシステムに適切な保護機構を選択するのに苦労しています。適切なバルブが設置されていないと、小さな誤動作が重大な事故に発展する可能性があります。そこで活躍するのがリリーフバルブであり、損害が発生する前に過剰な圧力を自動的に逃がし、システムを保護します。リリーフバルブは、あらかじめ設定された圧力で自動的に開き、余分な液体やガスを放出することで、システムの過圧を防ぐように設計された安全装置です。圧力が安全なレベルに戻ると、バルブは再び閉じ、通常の運転を再開します。なぜリリーフバルブが必要なのか?圧力 [...]

ニードルバルブの取り付け方法:産業用システムのためのステップバイステップインストール

産業用流体システムは精度と信頼性に依存していますが、正しく設置されていなければ、どんなに優れたコンポーネントでも故障します。多くのエンジニアがニードルバルブの取り付けに苦労しており、漏れ、圧力低下、バルブの故障につながっています。これらの問題はオペレーションを停止させ、安全上の危険を引き起こす可能性があります。幸いなことに、ニードルバルブの正しい取り付けは、正しい手順に従えば簡単です。このガイドでは、各工程を順を追って説明し、ベストプラクティスを強調し、コストのかかるミスを避けるお手伝いをします。ニードルバルブの取り付けには、互換性のチェック、接続部の洗浄、必要に応じてネジシーラントの塗布、流れ方向の調整、慎重な締め付け、リークテストが必要です。正しい取り付けは、信頼できる流量制御を保証し、システムの故障を防ぎます。

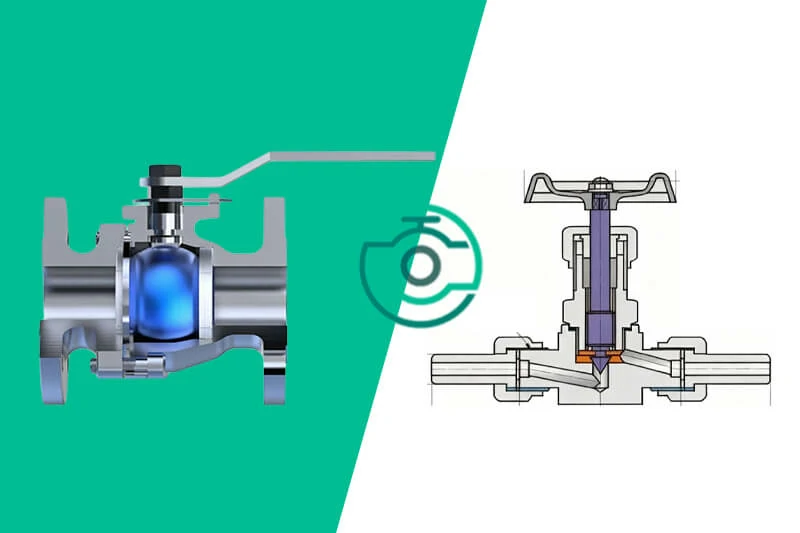

ボールバルブとニードルバルブ:主な違い

正しいバルブの選択は、特にボールバルブとニードルバルブのどちらを選ぶか迷うものです。特に、ボールバルブとニードルバルブのどちらを選ぶか迷うことがあります。間違ったものを選ぶと、流量制御がうまくいかず、安全性に問題が生じたり、システムの効率が悪くなったりすることがあります。この記事では、構造的、機能的な違いを説明し、より多くの情報に基づき、費用対効果の高い購入を決定できるようにします。ボールバルブは迅速なシャットオフを提供し、オン/オフ流量制御に最適ですが、ニードルバルブは段階的な調整で正確な流量調節を可能にします。ボールバルブは迅速な操作と耐久性を必要とするシステムで一般的に使用されるのに対し、ニードルバルブは計測機器や細かい制御を必要とするアプリケーションに適しています。それぞれのバルブがどのように機能し、どのような場所で使用され、どのような特徴があるのかを探ってみましょう。

ダブルブロック&ブリードバルブはどこで使うのか?

重要な流体システムにおいて、漏れは単なる厄介事ではなく、重大な安全性と運転上のリスクです。多くの工業用バイヤーが高信頼性隔離に適したバルブの選択に苦慮しています。標準的なバルブでは不十分な場合、ダブルブロック&ブリードバルブがミッションクリティカルなアプリケーションに安全で省スペースなソリューションを提供します。ダブルブロック&ブリードバルブ(DBB)はメンテナンス、安全性、製品の完全性のために絶対的な隔離が必要な高圧、高リスクのシステムで使用されます。一般的な使用例としては石油やガスのパイプライン、化学処理ライン、計装システムなどが挙げられます。DBBバルブは2つのシーリング面の間に閉じ込められた媒体を積極的に隔離し、ブリードします。ここではダブルブロック&ブリードバルブがどのような用途に使われるのか、またその理由を探ってみましょう。

計量バルブの役割は?

流体制御システムでは、精度と一貫性がすべてです。しかし、多くのバイヤーやエンジニアは、一般的なバルブの種類を見分けるのに苦労しています。間違ったバルブの選択は、不正確な吐出、不安定なシステム性能、または費用のかかる流体の過剰使用を意味します。従って、定量バルブは何をするものなのか、また、お客様のプロセスの中でどのような位置づけにあるのかを理解することは、より賢く、より効率的な選択をするために不可欠なのです。計量バルブは、バルブの開口部の大きさを調整することにより、液体や気体の流量を正確に制御し、計装システムやプロセス制御システムにおいて、スムーズで正確、かつ再現性のある流量調整を可能にします。石油・ガス、化学処理、計装設計のいずれに携わる方であっても、その仕組みを理解 [...]...

ブリーダー・フィッティングとは?

産業用システムでは、閉じ込められた圧力は危険であり、メンテナンスの遅れはコストがかかり、不適切なベントはシステム故障の原因になります。多くのエンジニアやバイヤーは、ブリーダー・フィッティングのような小さなコンポーネントの重要性を過小評価しています。だからこそ、ブリーダー・フィッティングとは何か、どのように機能するのか、そしてどこに適用されるのかを理解することが、安全で効率的な運転を確保するために重要なのです。この記事では、ブリーダー・フィッティングの定義、機能、用途、選択のヒントを詳しく説明し、十分な情報に基づいた調達の決定をお手伝いします。ブリーダー・フィッティングは、計装システム、油圧回路、またはパイプライン・アセンブリから、閉じ込められた圧力や残留流体を安全に逃がすために設計された、小型で精密なコンポーネントです。これらは一般的に、システム[...]中に使用されます。

プレスイン・グリース・フィッティングの取り付け方

多くの技術者やメンテナンス・チームが、グリース漏れや早期故障を起こさずに圧入式グリース・フィッティングを正しく取り付ける方法をよく尋ねます。誤った取り付けは、グリースの吹き出し、継手のゆるみ、あるいはベアリングの損傷を引き起こす可能性があります。このガイドでは、あらゆる産業用途で確実で信頼性の高い潤滑を確保できるよう、正しい取り付け方法を説明します。圧入式グリース・フィッティングを取り付けるには、潤滑穴を十分に清掃し、正しい内径サイズを確保し、フィッティングの位置を合わせ、完全に収まるまでソケットまたはドリフトを使用してまっすぐ所定の位置に叩き込んでください。適切に取り付けられた圧入式グリース・フィッティングは、きつく、平らで、グリースが漏れずに潤滑チャネルに直接供給されるように配置されていなければなりません。これで [...]...

計量バルブ総合ガイド

工業エンジニアやバイヤーは、定量バルブとは何か、ニードルバルブや他の流量制御部品と違うのか、とよく質問します。これを誤解すると、流れの安定性が悪くなり、投与が不正確になり、不必要なシステムのダウンタイムが発生します。これらの問題を解決するために、このガイドでは、定量バルブの役割、仕組み、正しいバルブの選び方について説明します。定量バルブは、非常に小さく、安定した、再現性のある液体または気体の流量を調整するために設計された精密流量制御バルブです。細かくテーパーをつけた多回転ステムを使用し、段階的な微小調節を可能にするため、サンプリング、化学薬品注入、潤滑剤計量、計装システムなどに不可欠です。標準的なニードルバルブとは異なり、計量バルブははるかに[...]を提供します。

バルブアセンブリのブリーダーボンネットとは?

多くの工業用バルブシステムにおいて、メンテナンスエンジニアはしばしば、シャットオフ後もバルブキャビティ内に閉じ込められた残圧という繰り返し発生する問題に直面します。この隠れた圧力は、適切に排出されない場合、深刻な安全上の危険やコストのかかるダウンタイムにつながる可能性があります。この問題を解決するために、エンジニアはブリーダーボンネットと呼ばれる特殊な部品を使用します。ブリーダーボンネットはバルブアセンブリに取り付けられる圧力保持部品で、バルブ本体部またはキャビティ内の閉じ込められた圧力を安全に逃がす経路を提供します。これにより、分解や点検の前にメンテナンス担当者がバルブ室内の残留流体やガスを手動で逃がすことができ、[...]を低減することができます。