Overview

Water Valves’ Double Block & Bleed (DBB) valve offers a compact, high-integrity solution for critical isolation and venting in high-pressure systems. Designed to replace complex multi-valve assemblies, our DBB valves integrate two isolation valves and one bleed valve in a single body—saving space, weight, and reducing potential leak paths. Ideal for oil & gas, petrochemical, and offshore platforms.

Product Features:

Dual isolation + central bleed function

Compact one-piece forged or bar stock body

Available in ball/ball, needle/needle, or needle/ball combinations

Blowout-proof stem design

Fire-safe & anti-static design (API 607 compliant)

Suitable for horizontal or vertical installation

Available in flanged, threaded, or welded end connections

Categories

Features

- Maximum working pressure: 10,000 psig (690 bar)

- Special design to enable lubricant or sealant to flow around the spring and through the opening on the sides of

the retainer smoothly - All-metal construction, applicable in both high and low temperature environments

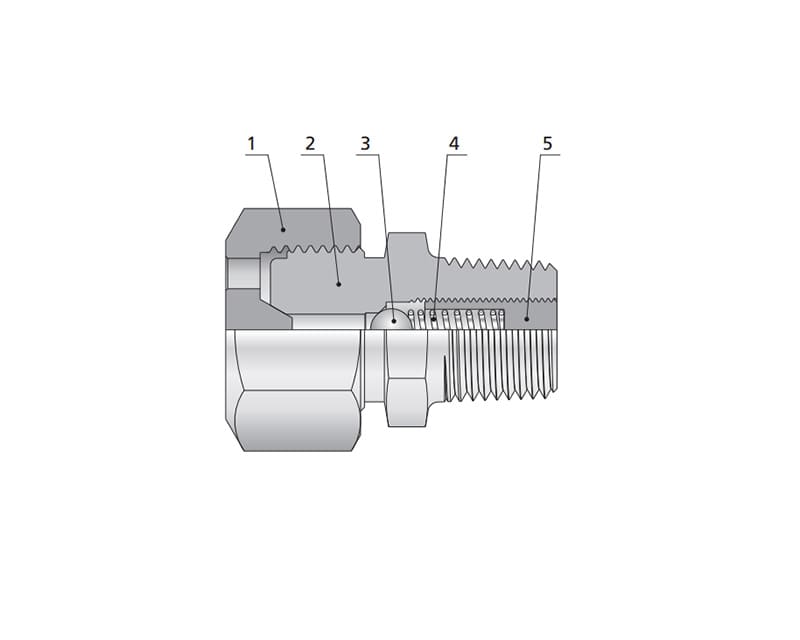

Component

No. | Component | Carbon Steel | SS 316 |

|---|---|---|---|

1 | Vent Cap | CS (Zinc) | SS 316/A479 |

2 | Body | CS (Zinc) | SS 316/A479 |

3 | Ball | 316/A276 | Tungsten Carbide |

4 | Spring | X-750/AMS 5699 | X-750/AMS 5699 |

5 | Retainer | SS 316/A479 | SS 316/A479 |

Technich Data

Considerations When Buying Grease Fittings

End connections

NPT 1/4″, 3/8″, 1/2″, 3/4″, 1″

GAS 3/8″, 1/2″

Working pressure

Working pressure up to: 10,000 psig (690 bar)

Available material

A105 LF2

304 Stainless Steel 316L Stainless Steel

Alloy 400 Alloy 625 Alloy C-276

Duplex 2205 Duplex 2207

NOTES: other products or different fittings designs are available on request; all measures are in millimeters.

Benefit From Your Committed Valves and Fittings Manufacturer

Free Fittings Sample

Walter offers you a free fitting sample for testing and to confirm that we met your custom design requirements.

Wholesale Fitting Price

Our high-quality fittings are available at wholesale rates which saves you money and reduces your costs of production.

Low Minimum Order Quantity

All our clients are important to us and thus our MOQ is 10 pieces to accommodate large and small orders.

High Bottle Quality

We are meticulous with our quality checks and manufacturing standards. Our goal is to offer you the best glass bottles.

Worry-free Aftersale Services

The Walter team is always on hand to guide you through aftersale procedures such as warehousing, shipment, and just-in-time delivery.

FAQ

A: A double block and bleed (DBB) valve combines two isolation valves and one bleed valve into a single compact body. It ensures complete isolation of process media for maintenance, pressure relief, or safety checks, while minimizing the risk of leakage from upstream lines.

A: We offer multiple configurations, including ball-ball, needle-needle, and needle-ball combinations. Selection depends on the application’s pressure class, flow media, and control requirements.

A: DBB valves are widely used in oil & gas, petrochemical, chemical processing, power generation, and offshore drilling—especially for pressure transmitter isolation, chemical injection, and pipeline maintenance.

A: Yes. Our DBB valves are available with threaded (NPT/BSP), flanged (ASME B16.5), socket weld, or butt weld ends. Custom end connection types are also supported on request.

A: All valves undergo 100% hydrostatic and seat leakage testing per API 598. We also offer fire-safe certification (API 607), NACE MR0175 compliance, CE marking, and third-party inspection if required.

Ready to Source Reliable Valve Solutions?

At Water Valves, we specialize in precision-engineered valves and fittings built to perform in the world’s most demanding industries. Whether you need standard components or custom solutions, our team is here to support your project needs.