Grease Fittings

Overview

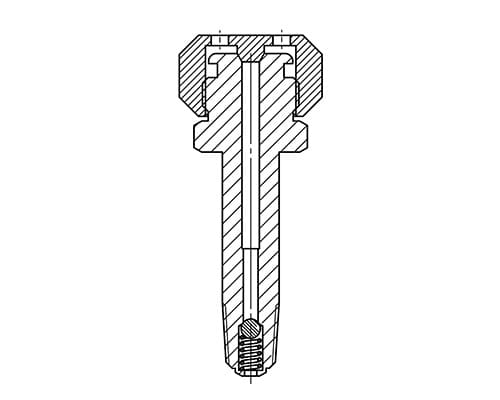

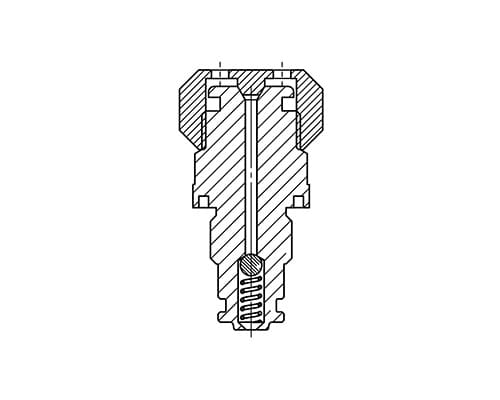

Grease Fittings are installed onto the seat and stem of valves. Leakage may occur when the sealed part wears off or for other reasons.

The leakage will be sealed temporarily by injecting the grease through the grease fitting to secure time for remedial measures.

Features

- Maximum working pressure: 10,000 psig (690 bar)

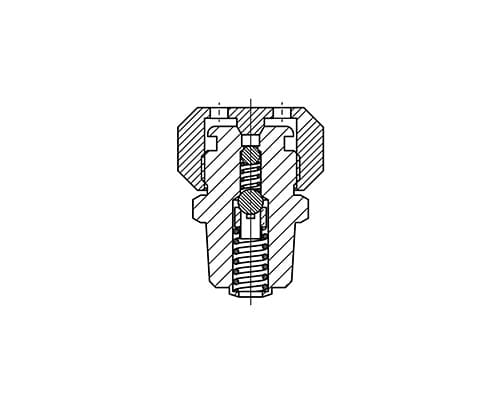

- Special design to enable lubricant or sealant to flow around the spring and through the opening on the sides of the retainer smoothly

- All-metal construction, applicable in both high and low temperature environments

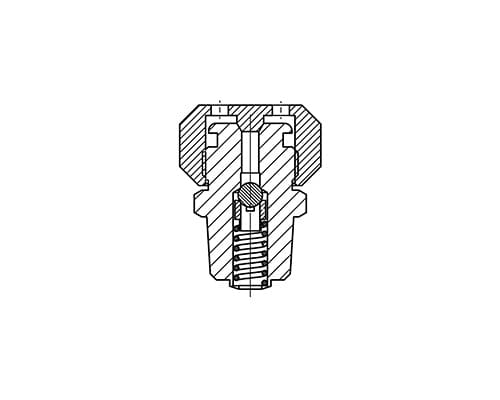

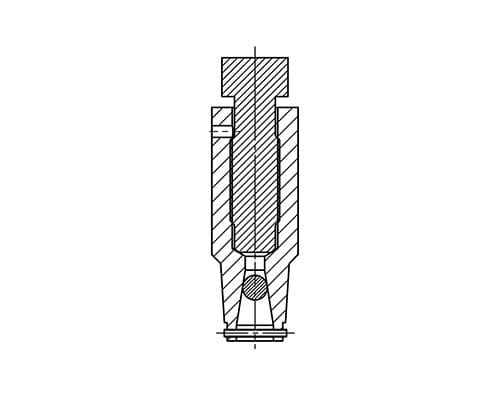

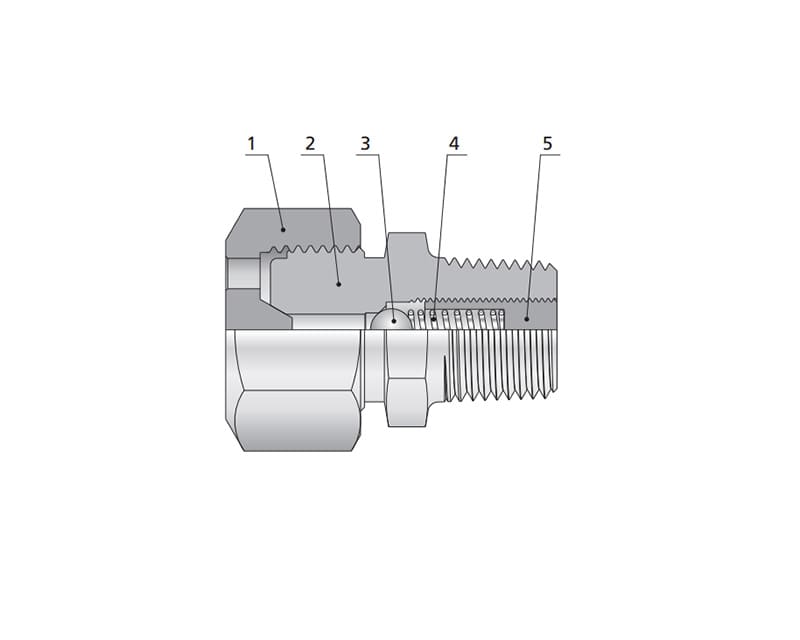

Component

No. | Component | Material(CS) | Material(SS316) |

|---|---|---|---|

1 | Vent Cap | CS (Zinc) | SS 316/A479 |

2 | Body | CS (Zinc) | SS 316/A479 |

3 | Ball | 316/A276 | Tungsten Carbide |

4 | Spring | X-750/AMS 5699 | X-750/AMS 5699 |

5 | Retainer | SS 316/A479 | SS 316/A479 |

Technich Data

Considerations When Buying Grease Fittings

End connections:

1/4″ NPT, 3/8″ NPT, 1/2″ NPT, 3/4″ NPT, 1″ NPT

3/8″GAS, 1/2″GAS

Max Operating Pressure:

10,000 psig (690 bar)

Plating Type:

Zinc | N/A

Ball Material:

316L Stainless Steel

Tungsten Carbide

Consult factory for additional materials

Body Material:

A105 LF2

304 Stainless Steel 316L Stainless Steel

Alloy 400 Alloy 625 Alloy C-276

Duplex 2205 Duplex 2207

Consult factory for additional materials

Spring Material:

Inconel X-750

Consult factory for additional materials

NOTES: other products or different fittings designs are available on request; all measures are in millimeters.

FREQUENTLY ASKED QUESTIONS

Grease allows grease to pass in one direction but not the other through one-way check valves. Inside the fitting is a spring-suspended ball check valve. As the grease is pushed into the fitting, pressure is created on the ball check valve of the compression spring, allowing the oil to pass entirely through the fitting. When the grease flow stops, the spring pushes the ball check valve back into place, closing the fitting and preventing grease overflow.

Make sure you have a pushbutton head coupler attached to your grease gun.

- Clean the pushbutton head grease connector for any contamination or debris.

- Slide the knob coupling over the grease coupling to interlock the grease coupling with the coupling.

- Start pumping grease from the grease gun until the desired amount is reached.

Remove grease connector from connector by sliding grease connector over grease connector.

- Oil and Gas

- Petrochemical

- Chemical

Benefit From Your Committed Valves and Fittings Manufacturer

Free Fittings Sample

Walter offers you a free fitting sample for testing and to confirm that we met your custom design requirements.

Wholesale Fitting Price

Our high-quality fittings are available at wholesale rates which saves you money and reduces your costs of production.

Low Minimum Order Quantity

All our clients are important to us and thus our MOQ is 10 pieces to accommodate large and small orders.

High Bottle Quality

We are meticulous with our quality checks and manufacturing standards. Our goal is to offer you the best glass bottles.

Worry-free Aftersale Services

The Walter team is always on hand to guide you through aftersale procedures such as warehousing, shipment, and just-in-time delivery.