An instrument manifold is a critical component in process control systems, designed to simplify the distribution, regulation, and isolation of fluids or gases in industrial applications. Whether used in oil and gas, chemical processing, or HVAC systems, manifolds improve efficiency, safety, and maintenance operations. If you’re looking to optimize your fluid or gas control system, understanding how manifolds work and their benefits will help you choose the right solution for your needs. Let’s take a deeper look at the basic aspects of instrument manifolds and their role in modern industrial settings.

What Are the Main Functions of a Manifold?

Коллектор для инструментов acts as a centralized connection hub, efficiently linking multiple process instruments to a single process line. These components replace numerous individual fittings with an integrated block design, fundamentally transforming complex instrumentation networks. In practical applications, this integration greatly reduces the number of potential leak paths while simplifying system layout and maintenance procedures.

The intelligent design of manifolds includes strategically placed valves that enable essential functions such as instrument isolation, calibration, and system venting—all achievable without interrupting continuous process operations. This functionality is especially valuable in pressure measurement systems, where 2-valve or 5-valve configurations offer flexible control options for operators.

In addition to basic connectivity, manifolds also improve measurement accuracy by maintaining balanced pressure distribution between connected devices and minimizing response time delays through optimized internal volume.

How Important Are Manifolds in Industrial Systems?

Instrument manifolds play a vital role in various aspects of system performance within industrial operations. These components form the backbone of reliable process instrumentation by eliminating the need for a complex network of individual valves and fittings. Their integrated design offers measurable improvements in key areas: reduced installation complexity through fewer connection points, which translates to lower leak risks and simpler troubleshooting.

The ability of a manifold to isolate instruments from process conditions significantly enhances safety, allowing maintenance without full system shutdown or exposure to hazardous media. Measurement accuracy also improves due to stable pressure conditions and reduced response lag.

From an economic perspective, while high-quality manifolds involve a larger initial investment, they often deliver significant long-term savings by reducing maintenance demands, minimizing leak-related losses, and cutting production downtime.

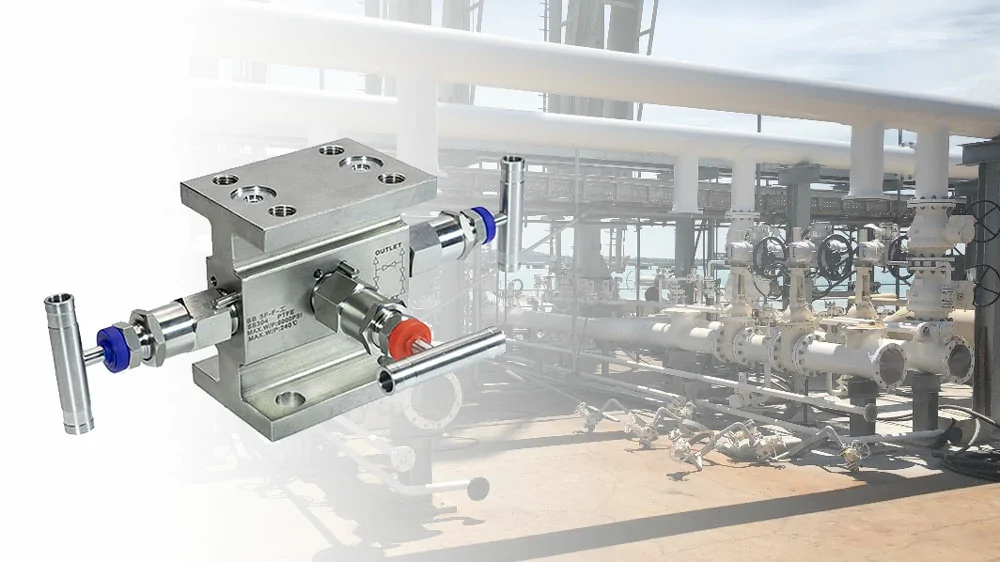

In critical applications such as refinery operations or chemical injection systems—where failure can result in inaccurate data or hazardous situations—properly specified manifolds are indispensable. Therefore, choosing the right manifold configuration and materials is essential during system design, as factors such as process media characteristics, operating conditions, and maintenance needs all influence the optimal specifications.

Modern manifold designs combine precision engineering with corrosion-resistant materials to ensure reliable performance across diverse industrial environments, while standardized connection patterns make system modifications easier.

Why Use an Integrated Manifold Instead of Separate Fittings?

The adoption of integrated manifolds in industrial systems represents a major improvement over traditional setups with separate fittings, offering numerous operational advantages that enhance overall system performance.

The primary benefit is the significant reduction in potential leak paths, achieved by minimizing the number of threaded connections. This not only increases reliability but also allows for a more compact installation—particularly valuable in space-constrained control panels or complex piping layouts.

Integrated manifold configurations greatly simplify maintenance, with built-in features such as isolation valves enabling instrument calibration or replacement without disrupting the process. A typical example is the five-valve integrated manifold, which offers comprehensive control within a compact unit, including process isolation, pressure balancing, and safe fluid venting.

For industries like oil and gas production, where uptime is critical, these maintenance benefits directly result in reduced downtime and improved operational efficiency.

Standardized manifold designs further boost system flexibility by simplifying component replacement or system expansion, ensuring long-term scalability as operational demands evolve.

What Is the Purpose of a Rooftop Manifold?

Rooftop manifolds perform a specialized distribution role in building systems. While different from their counterparts in process industries, they follow similar principles of centralized flow control.

These components act as key distribution points in large HVAC systems, transferring flow from the main supply line to multiple duct branches, ensuring balanced airflow throughout a building. Rooftop manifold designs prioritize even flow distribution and pressure management to ensure optimal performance across all connected zones.

In fire protection applications, rooftop manifolds are equally critical, distributing water or extinguishing agents to sprinkler systems. Their design ensures stable pressure at all outlets, allowing for reliable emergency response.

Rooftop installations face environmental challenges, requiring specific construction features such as corrosion-resistant materials and weatherproof housings to withstand long-term outdoor exposure. These technical demands have led to the development of rugged manifold solutions tailored for rooftop use, featuring durable materials and precision flow control mechanisms to meet the high standards of modern building systems.

The operational reliability of these components is essential, as they directly affect climate control effectiveness and the performance of life safety systems.

What Are the Different Types of Instrument Manifolds?

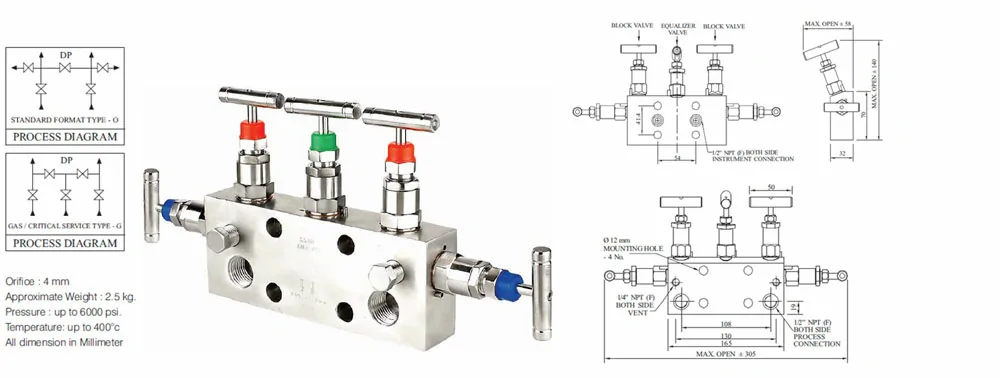

Instrument manifolds come in various configurations to meet different industrial needs. The most common types include 2-valve, 3-valve, and 5-valve manifolds, each designed for specific functions in process measurement and control.

Two-valve manifolds provide basic isolation functions, while the three-valve version adds a balancing feature. The five-valve manifold offers the most comprehensive control, with additional ports for venting and calibration.

Other specialized variants include block-and-bleed manifolds for critical safety applications, mini-manifolds for installations with limited space, and high-pressure manifolds for extreme operating conditions.

The choice of manifold type depends on factors such as process requirements, safety considerations, and maintenance needs.

Заключение

Instrument manifolds are indispensable in modern process control, offering advantages such as simplified installation, enhanced safety, and improved system efficiency.

For expert guidance on manifold selection, installation, or customization, contact our engineering team today or browse our catalog of industry-leading solutions.

By selecting the right manifold configuration, you can ensure optimal system performance, reliability, safety, and long-term value.