A check valve is a crucial mechanical device designed to allow fluid flow in one direction while automatically preventing reverse flow (backflow) in piping systems. Whether you’re looking for a standard swing check valve, a backflow-preventing double check valve, or a specialized sump pump check valve, understanding these components is essential for engineers, plumbers, and maintenance professionals across industries.

This comprehensive guide explains how check valves function, their various types, industrial applications, and selection criteria to optimize your fluid systems.

Continue reading to discover the engineering principles behind check valves, their critical role in protecting equipment, and how to choose the ideal configuration for your specific application needs.

How Does a Check Valve Work?

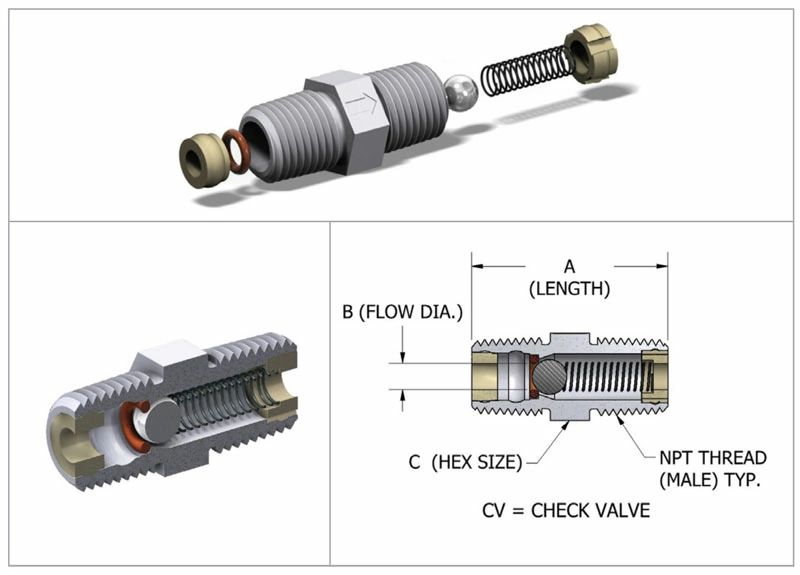

Check valves operate on a simple but effective principle of differential pressure and mechanical movement. When fluid flows in the desired direction (forward flow), the pressure forces the valve’s closing mechanism (such as a disc, ball, or diaphragm) to open against a spring or gravity force.

The specific opening mechanism varies by valve type. Swing check valves use a hinged disc that swings open, while lift check valves employ a piston-like disc that rises vertically.

Once forward flow stops or reverses, the closing mechanism automatically returns to its seated position through spring tension, gravity, or backflow pressure, creating a positive seal that prevents reverse flow. This entire process happens without any manual intervention or external control, making check valves fully automatic flow control devices.

The cracking pressure (minimum upstream pressure required to open the valve) and closing characteristics differ significantly between check valve types. For instance, a wafer check valve might open at 0.5 psi, while a heavy-duty nozzle check valve may require 5–10 psi.

Modern designs incorporate features like quick-closing mechanisms to prevent water hammer and soft-sealing materials for bubble-tight shutoff. The valve’s internal geometry is carefully engineered to minimize pressure drop during forward flow while ensuring rapid, positive closure when flow reverses.

These design considerations make check valves indispensable for protecting pumps, compressors, and other equipment from damage caused by backflow or system pressure surges.

What Is the Purpose of a Check Valve in Industrial Systems?

In industrial applications, check valves serve three primary functions that make them essential components in fluid handling systems.

First and foremost, they prevent backflow that could damage sensitive equipment. Pumps, for example, can suffer severe impeller damage from reverse rotation caused by backflow.

Second, check valves maintain system prime by preventing fluid drainage from elevated pipes or equipment when pumps shut down. This is particularly critical in irrigation systems, fire protection lines, and vertical pipe runs where fluid column maintenance is essential.

Third, they prevent contamination between different fluid streams in complex piping networks, acting as a fail-safe against cross-contamination in chemical processing, food production, and water treatment plants.

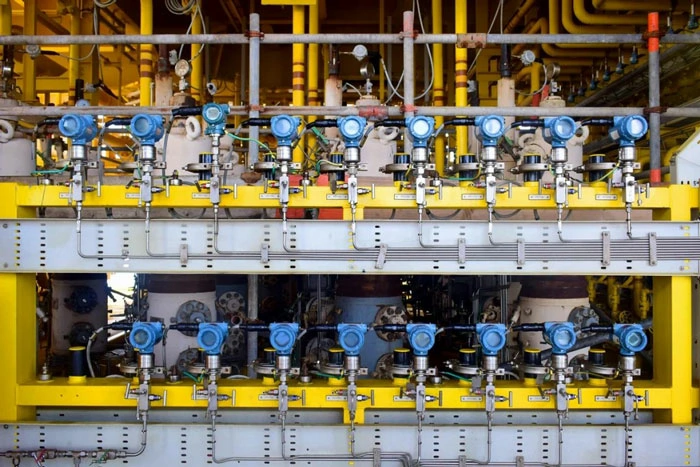

Beyond these core functions, check valves play specialized roles in various industries. In oil and gas operations, they prevent dangerous backflow in wellhead equipment and pipeline systems. Power plants use them to protect turbines from steam backflow during shutdowns. HVAC systems rely on check valves to maintain proper refrigerant flow direction and prevent compressor damage. The pharmaceutical industry utilizes ultra-clean check valve designs to maintain sterile processing conditions.

What Are the Main Types of Check Valves?

The industrial market offers numerous check valve configurations, each optimized for specific performance characteristics and application requirements.

Swing check valves: Featuring a hinged disc that swings open with flow, these are among the most common types, offering low pressure drop and suitability for horizontal pipe runs.

Lift check valves: Use a guided disc that moves vertically with flow, making them effective for high-pressure systems and vertical installations.

Ball check valves: Employ a free-floating or spring-loaded ball as the closing mechanism, excelling in viscous fluid services and applications requiring quick closure.

Dual-plate wafer check valves: Provide compact, lightweight solutions for space-constrained installations.

Tilting disc check valves: Combine the low pressure drop of swing checks with faster closing characteristics.

Nozzle check valves: Offer extremely rapid closure to prevent water hammer in high-velocity systems.

Each type has distinct advantages. For instance, spring-loaded inline check valves can be installed in any orientation, while gravity-dependent swing checks typically require horizontal mounting with proper disc orientation.

Material selection also varies significantly, from brass and bronze for water services to stainless steel and exotic alloys for corrosive or high-temperature applications.

Choosing the Right Check Valve for Your System

Selecting the appropriate check valve requires careful evaluation of multiple system parameters to ensure reliable performance and longevity.

Engineers must first consider flow characteristics — the valve’s size and design should match the system’s flow rate to maintain proper disc positioning and minimize turbulence.

Pressure ratings must accommodate both normal operating pressures and potential surge conditions, with special attention to the valve’s closing pressure characteristics. Fluid compatibility dictates material selection for both the valve body and internal components, particularly with corrosive, abrasive, or high-purity media.

Installation orientation significantly impacts performance, as some check valve types rely on gravity for proper disc return while others use springs for orientation-independent operation.

Maintenance requirements vary widely too. While most check valves are designed for minimal maintenance, some designs allow for easy inspection and seal replacement without full removal from the pipeline.

Industry standards like API 594 for wafer check valves or AWWA C508 for swing check valves provide important benchmarks for quality and performance.

Additional considerations include the need for quick closure to prevent water hammer, allowable pressure drop, and compatibility with system cleaning procedures like CIP (clean-in-place) in food/pharmaceutical applications.

A properly specified check valve will provide years of trouble-free service, while an incorrect selection can lead to premature failure, excessive maintenance, or even system damage.

Why Valve Distributors Prefer Waltervalves for Bulk Check Valve Supply

Industry-leading valve distributors consistently choose Waltervalves as their primary check valve supplier due to several competitive advantages in bulk supply scenarios.

Our manufacturing facilities maintain extensive inventories of standard check valve configurations while offering custom engineering capabilities for specialized applications. This dual capacity enables distributors to meet diverse customer needs from stock while having access to engineered solutions for unique requirements.

Waltervalves’ stringent quality control processes, certified to ISO 9001 and API standards, ensure every valve meets exacting performance specifications right out of the box.

For distributors, our value proposition extends beyond product quality to include comprehensive logistical support. Regional warehouse locations enable rapid order fulfillment, while our barcoded packaging simplifies inventory management.

Technical support teams provide product training and application engineering assistance to help distributors serve their customers more effectively. Our competitive pricing structure, combined with volume-based incentive programs, delivers superior margin opportunities.

Perhaps most importantly, Waltervalves has built a reputation for reliability. When distributors source from us, they can be confident the products will perform as specified, reducing warranty claims and protecting their brand reputation in the market.

Conclusion

Check valves play an indispensable role in protecting fluid systems across countless industries, from municipal water supplies to chemical processing plants. Their automatic operation prevents costly equipment damage, maintains system efficiency, and safeguards against dangerous backflow situations.

Understanding the various types — from basic swing checks to sophisticated dual-plate designs — enables engineers to specify the optimal solution for each unique application. Proper selection criteria must account for fluid properties, flow characteristics, pressure conditions, and installation requirements to ensure long-term reliable performance.

For distributors and end-users alike, choosing a trusted supplier like Waltervalves guarantees access to high-quality check valves backed by engineering expertise and reliable supply chain support.

Our extensive product range covers all major check valve types in materials ranging from standard brass to exotic alloys for extreme service conditions. Technical specialists are available to assist with product selection, application troubleshooting, and custom engineering solutions.

Upgrade your fluid system protection today by exploring Waltervalves’ comprehensive check valve offerings. Contact our engineering team for personalized recommendations or request a product catalog to discover our full range of flow control solutions. For immediate needs, browse our in-stock selection of API-compliant check valves available for quick shipment. Partner with Waltervalves for check valves that deliver unmatched reliability and performance in even the most demanding applications.