Bleeder and vent fittings are essential components in fluid and gas systems, designed to manage air, pressure, and unwanted materials within pipelines and equipment. While often confused, these fittings serve distinct roles across industries such as plumbing, HVAC, manufacturing, and automotive. Understanding their differences is key to optimizing system performance, enhancing safety, and ensuring efficient operation. This article clarifies the unique functions, applications, and selection criteria for bleeder and vent fittings. Bleeder fittings are designed to release or drain fluids or gases from a system, often for maintenance, pressure reduction, or sampling, while vent fittings specifically remove air or gases to prevent airlocks, improve flow, and maintain system efficiency. Both are critical for safe and optimal operation in pipelines, compressors, and hydraulic systems.

Continue reading to explore how these fittings work, where they are used, and how to choose the right type for your application.

What Is the Purpose of a Bleeder Valve?

A bleeder valve is primarily used to release fluids or gases from a system for purposes such as maintenance, pressure relief, or fluid sampling. These valves are commonly found in hydraulic systems, radiators, compressors, and fuel systems where trapped air or excess pressure could impair functionality or safety. By allowing controlled discharge, bleeder valves help in reducing pressure, removing contaminants, or preparing equipment for shutdowns. They are especially useful in high-pressure environments where safe fluid evacuation is necessary to avoid accidents or equipment damage.

How Does a Vent Fitting Work in a Pipeline?

Vent fittings serve to automatically or manually release unwanted air or gases from pipelines, tanks, or closed systems. Their primary function is to prevent airlocks, which can restrict flow, cause corrosion, or reduce system efficiency. In heating systems, for example, automatic air vents release trapped air to ensure consistent water circulation and heat distribution. These fittings often contain a float mechanism that closes the valve when liquid is present and opens it when air accumulates. This design helps maintain continuous operation without manual intervention, making them vital in HVAC, water supply, and industrial processing systems.

Are Bleeder and Vent Fittings Interchangeable?

Although bleeder and vent fittings may appear similar, they are not generally interchangeable due to functional and design differences. Bleeder valves are built for draining liquids or gases, often under pressure, and usually feature robust construction to handle frequent operation and high stress. Vent fittings, on the other hand, are specifically engineered to release air and are commonly used in scenarios where air entrapment is a primary concern. Using a bleeder valve in place of a vent fitting—or vice versa—could lead to inefficiency, leakage, or safety issues. It is important to select the fitting based on the specific system requirements.

What’s the Typical Size Range of Bleeder vs Vent Fittings?

Bleeder and vent fittings are available in a wide range of sizes to accommodate different system dimensions and pressure ratings. Bleeder valves typically range from 1/8 inch to 1 inch in diameter, with larger sizes used in industrial drainage or pressure relief applications. Vent fittings usually vary between 1/8 inch and ½ inch, as they are designed for releasing air rather than moving significant volumes of fluid. The choice of size depends on factors such as flow rate, system pressure, and the type of medium being handled. Always consult engineering specifications or industry standards when selecting the appropriate size.

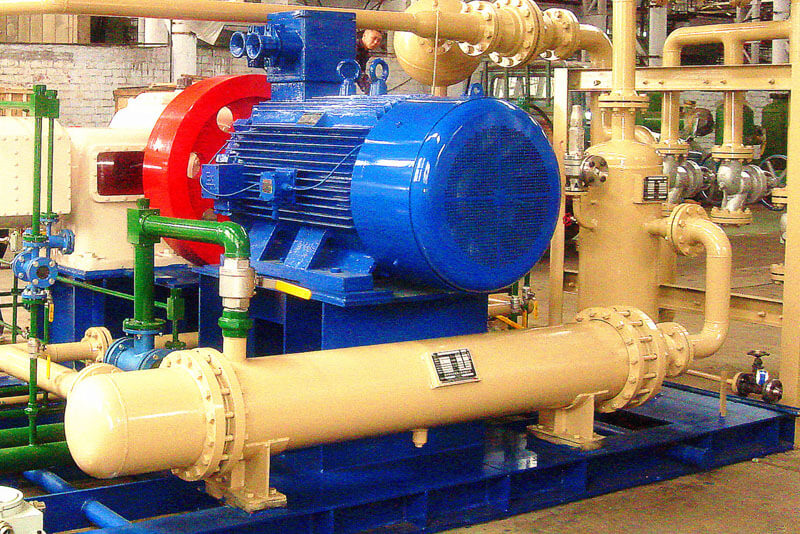

How Are Bleed Valves Used in Compressors?

In air compressors and gas systems, bleed valves play a critical role in managing pressure and ensuring safe operation. They are used to release compressed air during shutdowns to prevent restarting under load, which can protect the motor and reduce wear. In addition, bleed valves help remove condensation and contaminants that accumulate in compressor tanks. This not only enhances efficiency but also extends the equipment’s service life. In large-scale industrial compressors, automated bleed valves are often integrated into control systems for regular purging and maintenance.

What Is an Automatic Air Bleed Valve?

An automatic air bleed valve is a type of vent fitting designed to expel trapped air without manual operation. It contains a float or thermostatic element that rises when air is present, opening the valve to release air, and closes when liquid fills the chamber. These valves are widely used in hydronic heating systems, solar thermal installations, and coolant circuits to maintain uninterrupted flow and prevent air-related issues such as noise, corrosion, and reduced heat transfer. Their self-operating nature reduces maintenance needs and enhances system reliability.

How Do Bleed Valves Function in Water Lines?

In water supply and plumbing systems, bleed valves are used to drain sections of pipeline for repair, eliminate air pockets, or reduce pressure. They are often installed at low points in the system where water or sediment tends to accumulate. By periodically opening the valve, operators can remove trapped air or flush out debris, ensuring consistent water flow and pressure. In irrigation systems, for example, bleed valves help prevent freezing and damage during cold weather by allowing water to drain out. Their simple yet effective operation makes them valuable in both residential and commercial water systems.

Can Reddit Plumbing Advice Help Choose the Right Valve?

Online platforms like Reddit can provide practical insights and user experiences regarding the selection and installation of bleeder and vent fittings. Plumbing forums often feature discussions about common issues, such as choosing between automatic and manual valves, dealing with high-pressure environments, or troubleshooting leaks. However, while community advice can be helpful, it is essential to verify information with technical guidelines or professionals. Real-world experiences shared on forums may offer tips, but the final choice should be based on system specifications, safety standards, and manufacturer recommendations.

Which One Should Valve Buyers Choose—Bleeder or Vent?

For B2B buyers and engineers, the choice between bleeder and vent fittings depends on application requirements, system design, and operational conditions. Bleeder valves are preferable for draining fluids, reducing pressure, or handling maintenance tasks in liquid or gas systems. Vent fittings are the ideal solution for removing air and preventing airlocks in closed loops, tanks, or pipelines. Factors such as pressure rating, material compatibility, temperature, and automation needs should guide the selection process. Partnering with a trusted supplier ensures access to quality products and technical support tailored to industrial demands.

Conclusion

Bleeder and vent fittings serve unique and vital roles in ensuring the safety, efficiency, and reliability of fluid and gas systems. While bleeder valves focus on draining and pressure management, vent fittings specialize in air removal and preventing air-related issues. Understanding their differences helps in selecting the right component for applications ranging from plumbing and heating to industrial processing and compressors. If you are looking for high-quality bleeder or vent fittings, consider reaching out to our team for expert guidance and product solutions tailored to your needs. Explore our product catalog or contact us today for more information and technical support.