Types of Grease Fittings and Their Functions

In many industrial and mechanical systems, insufficient lubrication leads to premature bearing wear, downtime, and high maintenance costs. Yet many engineers and maintenance teams overlook one simple but critical factor — the type of grease fitting used. Without the right fitting, grease cannot reach friction points efficiently, resulting in wasted lubricant and equipment failure. Selecting […]

Check Valves and Flow Direction Control: How Do They Work and Why Do They Matter?

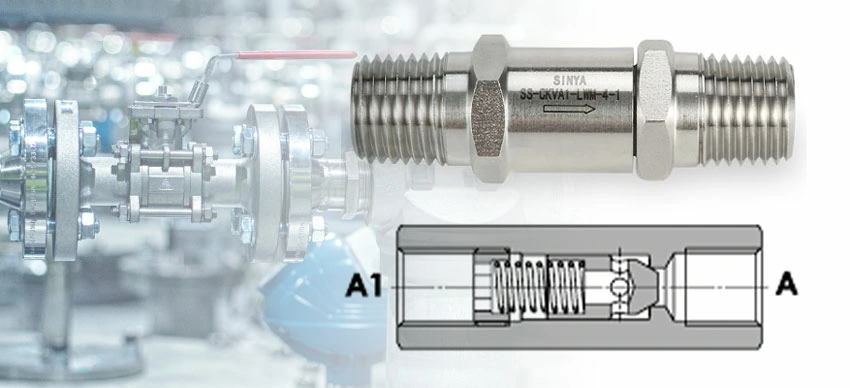

What is a check valve and how does it control flow direction? A check valve is a one-way valve that allows fluid (gas or liquid) to flow in only one direction, automatically preventing reverse flow through a mechanical mechanism like a disc, ball, or poppet. Why This Question Matters in Industrial Fluid Systems In B2B […]

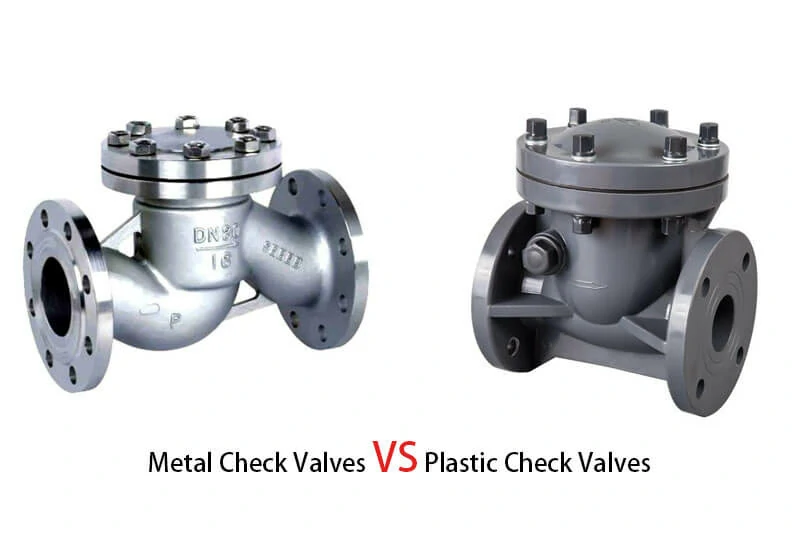

Metal vs Plastic Check Valves: Which Is Better?

Selecting the right check valve material may seem like a minor technical detail, but the consequences of choosing the wrong one can be costly. Many industrial buyers struggle with premature valve failure, chemical corrosion, or system inefficiencies, often because the valve material didn’t match the application. This makes understanding the key differences between metal and […]

What Is the Difference Between Bleeder and Vent Fittings?

Bleeder and vent fittings are essential components in fluid and gas systems, designed to manage air, pressure, and unwanted materials within pipelines and equipment. While often confused, these fittings serve distinct roles across industries such as plumbing, HVAC, manufacturing, and automotive. Understanding their differences is key to optimizing system performance, enhancing safety, and ensuring efficient […]

What Are Grease Fittings

Grease fittings, also known as zerks or grease nipples, are small but crucial components used in machinery and equipment to enable efficient lubrication of moving parts. They provide a standardized point for a grease gun to deliver lubricant directly into bearings, joints, and other friction-prone areas. This article explains what grease fittings are, how they […]

Where to Use Check Valves in a Piping System

Check valves are essential components in piping systems, designed to allow fluid to flow in one direction while preventing backflow that could cause damage or inefficiency. Understanding where and how to install these valves is critical for system safety, performance, and longevity. This article explores the key applications, types, and installation best practices for check […]

What Is an Instrumentation Ball Valve and How Does It Work?

An instrumentation ball valve is a specialized flow control device designed for precise regulation and isolation in analytical, measurement, and control systems. These compact, high-performance valves are essential components in process instrumentation, providing reliable shut-off for gases and liquids in pressure measurement, sampling, and chromatographic applications. Understanding the features of premium products like Parker instrumentation […]

What Is a Double Block and Bleed Valve?

A double block and bleed valve (DBB) is a critical safety component in industrial piping systems that provides reliable isolation and leakage prevention for hazardous fluid processes. This comprehensive guide explains the fundamental principles, applications, and advantages of double block and bleed technology, including specialized configurations like integral double block and bleed valve systems and […]

Check Valve vs Relief Valve: Key Differences

Check valves and relief valves are both essential components in fluid systems, but they serve fundamentally different purposes that are often confused. Understanding the difference between check valve and relief valve is crucial for proper system design and safety. While a check valve vs pressure relief valve may look similar in some cases, their operating […]

What Is a Check Valve?

A check valve is a crucial mechanical device designed to allow fluid flow in one direction while automatically preventing reverse flow (backflow) in piping systems. Whether you’re looking for a standard swing check valve, a backflow-preventing double check valve, or a specialized sump pump check valve, understanding these components is essential for engineers, plumbers, and […]